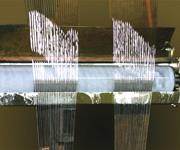

Glass Fibers

Structural polyurethanes: Bearing bigger loads

The versatile polymer shows new strength (and other advantages) in pultrusion and core materials applications.

Read MoreTeam-built bus body bests all

OEM meets tight development schedule on superlight multipart molded shell to offset propulsion system weight in fuel cell-powered transit bus.

Read MoreBoeing 787 Update

Approaching rollout and first flight, the 787 relies on innovations in composite materials and processes to hit its targets

Read MoreSizing Up Fiber Sizings

What glass fiber users need to know about sizings, and how new sizing developments are enhancing the performance of glass-reinforced composites.

Read MoreDesign Issues

Typical FRP pipe is reciprocally filament wound with a fiber angle of ±54.75° relative to the longitudinal (0°) axis. This architecture satisfies stress loads in both the circumferential (hoop) and longitudinal (axial) directions for most pipes and pressure vessels. It withstands the in-use pressure, ther

Read MoreSome Design Issues

A variety of resins can be used for offshore applications, depending on the requirements for the final product. General-purpose polyester offers a low-cost option that provides greater corrosion resistance than steel. Isophthalic polyester provides somewhat better corrosion resistance, while vinyl ester is pre

Read MorePetrobras Pioneers Topside Composites

Petrobras (Rio de Janeiro, Brazil) was the first major oil company to experiment with molded gratings in the 1980s, though these early products proved unsatisfactory due to wide variations in mechanical properties. However, advances in pultrusion and filament winding technology coupled with the availability of

Read MoreIssues With Design

Though steel is the traditional material for coiled tubing because of its low price, it is susceptible to corrosion, fatigue failure (caused by repeated coiling and uncoiling), and troublesome joints. In larger sizes, its weight can increase transport difficulties. With the advent of secondary recovery methods

Read MoreComposite Drilling Risers Many Years In The Making

The development of rigid composite riser systems has a history that spans two decades. Beginning in 1979, Aerospatiale and the Institut Français du Pétrole (IFP) developed a 15,000 psi, 4 inch composite tubular. Although this project started out as a feasibility study, by the mid-1980s it had led to the manufa

Read MoreOther Applications Expand

A growing area in the offshore world is the refitting or “recycling” of older oil platforms to support additional production. A particularly active area for recycling is in the North Sea, where additional pipelines can be run to existing rigs for about $1 million (as opposed to spending $20 million for a new r

Read More