Glass Fibers

Antiballistics: Better defense, less expense

Armor applications grow on the strength of new markets, new composite materials.

Read MoreLow-volume thermoplastics: Differential pressure molding

Cost-effective tooling and presses enable semi-automated prototyping and low-volume production of thermoplastic composites.

Read MoreCabin cruiser: Making the most of a mirror finish

The hull mirror-like gel coat finish on the Daedulus 30 cabin cruiser was achieved through a combination of Marine Concepts’ (Lee-on-the-Solent, Hampshire, U.K.) mold design experience and fabrication techniques and materials provided by Scott Bader (Wollaston, Northamptonshire, U.K.).

Read MoreBathware production: Feeder facilitates faster flow

Shower pans molder Just Trays Ltd. (Leeds, West Yorkshire) invests $1.6 million (USD) to improve its manufacturing processes, including the purchase of two of Model T5 Low Headroom Bulk Bag Dischargers from Spiroflow Ltd. (Clitheroe, Lancashire, U.K. and Monroe, N.C.).

Read MoreMaintaining fiber length in complex 3-D designs

Award-winning composite pallet showcases new LFT molding process from South Africa.

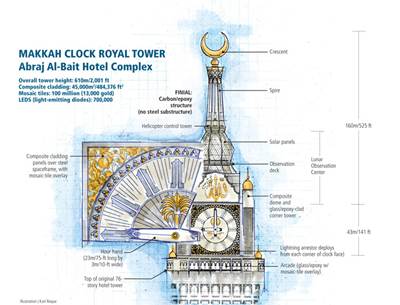

Read MoreBesting Big Ben: A Marvel in Makkah

Composite design makes possible the world’s largest clock and tallest clock tower.

Read MoreStructural armor or armored structures?

Either way, antiballistics engineers seek structural integrity and ballistic deterrence from a single design.

Read MoreLightweighting a heavyweight

Process combination produces significantly lighter overhead storage bins for big-rig sleeper cabs.

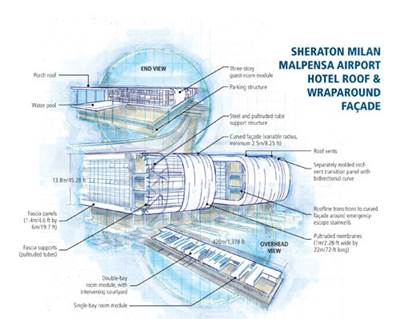

Read MoreHotel wrap: Curvilinear pultrusions

Airport hotel’s striking wraparound roofline made possible, durable and affordable with pultruded flat panels and profiled support structures.

Read MoreBuilding a bigger Big Wheel

Machining specialist scales up the 1970s icon, producing plugs and tools for an exact fiberglass replica at a Disney resort.

Read More