Glass Fibers

COBRA delivers GFRP covers for agricultural UAVs

COBRA’s drone covers use a composite laminate of glass fiber reinforcements combined with epoxy laminating resins in a hand laminated, vacuum bag consolidated production process.

Read MoreAdditive manufacturing reimagined: large-scale, fiber-reinforced thermoset printing

ORNL, MVP and Polynt-Reichhold launch world’s first commercially available, large-scale thermoset composite additive manufacturing machine and reactive print material.

WatchIFS expands line of filament wound FRP products

The company’s corrosion-resistant methacrylate-modified epoxy FRP pipe, duct and fittings can be engineered for a range of uses including chemical service environment applications.

Read MoreFET Ltd. launches laboratory-scale wet spinning system

Fibre Extrusion Technology Ltd.’s wet spinning production line is designed for early-stage formulation and process development of various fiber types.

Read MoreINEOS completes acquisition of Ashland Composites

Ashland’s Composites Business will become INEOS Composites, and will continue to provide gelcoats and glass fiber-reinforced plastic (FRP).

Read MoreNational Composites Week: Sustainability

As we celebrate National Composites Week, here are just a few of the many ways the composites industry is working toward a sustainable world.

WatchFiberCore Europe partners with Sustainable Infrastructure Systems to produce composite bridges in Australia

Patented technology used in more than 900 bridges and lock gates worldwide will have up to 40% recycled plastic by 2021.

Read MoreBEL launches new composites manufacturing and testing facility in Mumbai

New BEL facility to design and manufacture components using glass fiber reinforced polymer (GFRP) and carbon fiber reinforced polymer (CFRP) composites.

Read MoreAIT Bridges unveils composite tub girder bridge system

The fiber-reinforced polymer tub girder system provides an affordable, long term solution to traditional steel and concrete medium span deck bridges.

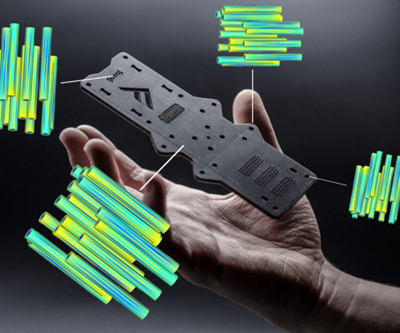

Read MoreMagnetic 3D printing the next generation of tailored composites

Fortify uses magnetic fields and digital light processing to produce tailored microstructures for high-resolution, 3D printed composite parts — and enables the next generation of multiscale, multifunctional composite metamaterials.

Watch