Defense

Merger mania, part II?

Columnist Dale Brosius considers the surges of company mergers that have affected the composites industry over the years.

Read MoreTriumph delivers first ramp structures for Boeing's V-22

The composite ramp and ramp door assemblies will be integrated onto the aft fuselage of the V-22 Osprey tiltrotor aircraft.

Read MoreAddcomposites introduces plug & play AFP/ATL for cost-effective composites manufacturing

New AFP-XS turns any robotic arm into an automated composites manufacturing system.

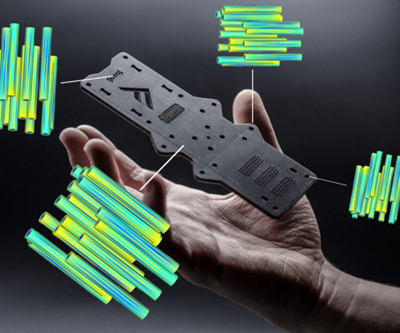

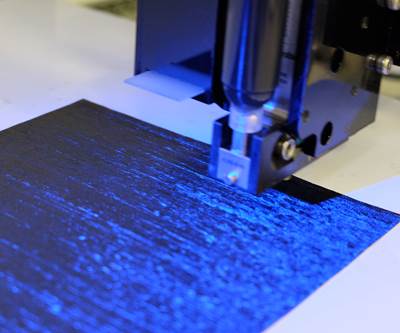

WatchMagnetic 3D printing the next generation of tailored composites

Fortify uses magnetic fields and digital light processing to produce tailored microstructures for high-resolution, 3D printed composite parts — and enables the next generation of multiscale, multifunctional composite metamaterials.

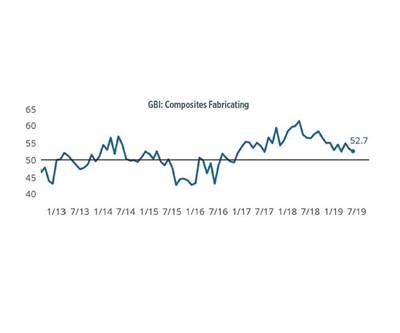

WatchEmployment activity leads expansion in business activity

The Composites Fabricating Index for June 2019 came in at 52.7, continuing its stretch of more than 30 months of expanding activity.

Read MoreClean Sky 2’s PASSARO project targets one-shot OOA composite cockpit

Synergies with MOSHO project for NDT, repair and also developing cobots for 70% cut in cycle time.

Read MoreInaugural National Composites Week to recognize, promote and celebrate composites manufacturing

From Aug. 26-30, 2019, composites manufacturers are encouraged to use social media, traditional media and in-person events to shine a light on the industry.

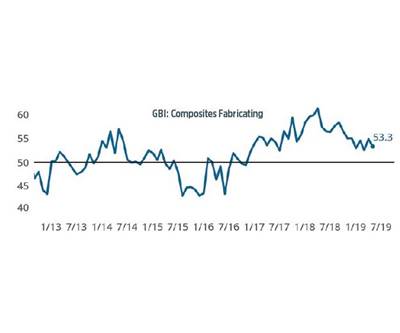

Read MoreIndex activity expands, led by production

The Composites Fabricating Index for May 2019 came in at 53.3, led higher by production activity.

Read MoreNanomaterials: Products, supply chain mature for next-gen composites

Development spans 3D and thermoplastic nanocomposites, nano-CMCs for hypersonics and nanomaterials safety and toxicity.

Read MoreGKN Aerospace thermoplastic composites featured on Bell V-280 Valor

The thermoplastic composite components will be used for a demonstrator of the military V-tail aircraft.

Read More