Compression Molding

Small wind gets big

Massive growth, complex blade designs reopen challenging market in wind energy niche.

Read MoreHigh-speed press cure for high-speed racers

Trapped tooling and compression molding bring cocuring efficiencies to previously autoclave-cured, aerodynamic fins and planes.

Read MoreSmall wind: Green energy gets greener

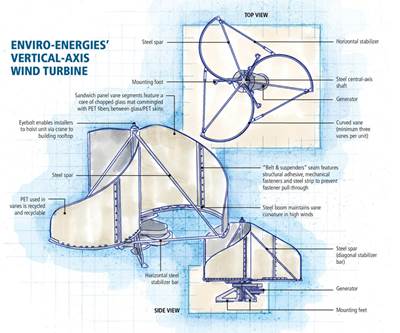

Kilowatt-rated vertical axis wind turbines supply green electric power where utility-scale turbines can’t.

Read MoreLow-volume thermoplastics: Differential pressure molding

Cost-effective tooling and presses enable semi-automated prototyping and low-volume production of thermoplastic composites.

Read MoreFuture combat helmet: Promising prototype

Tape laying, thermoforming methods hold hope for rapid coforming of thermoplastic shell and ballistic liner for U.S. Army’s future warfighter headgear.

Read MoreThermoformable thermoplastic composites

Thermoplastic composites that can be shaped into finished parts via thermoforming are proliferating as the thermoforming process gains traction, particularly in aerospace manufacturing. The following short article and chart provide some guidance in terms of sourcing.

Read MoreAerospace-grade compression molding

Continuous Compression Molding process produces structures 30 percent lighter than aluminum at costs that have both Airbus and Boeing sold.

Read MoreUBSs: Coming to North America

Common in Europe and Asia, the composite underbody shield might finally catch on in the U.S. and Canada.

Read MoreAutomated solution: New presses for SMC molding process

Using glass/polyester sheet molding compound (SMC) that it formulates and manufactures in-house, Stahlin Non-Metallic Enclosures (Belding, Mich.) produces composite boxes and enclosures for electrical systems and components.

Read MoreTaking Subjectivity out of Class A Surface Evaluation

Toward the goal of more consistent, repeatable and quantifiable Class A surface analysis, automakers and systems suppliers are developing and employing automated surface inspection tools.

Read More