Compression Molding

Event pavilion: SMC panels ensure architectural authenticity

To expand its services, the High Bullen golf and spa hotel in Devonshire, U.K., converts a little-used tennis facility into a flexible meetings facility, and kept the remodeled structure within the local "heritage" code with simulated mortared stone-like composite panels from Acell Industries Ltd. (Dublin, Ireland).

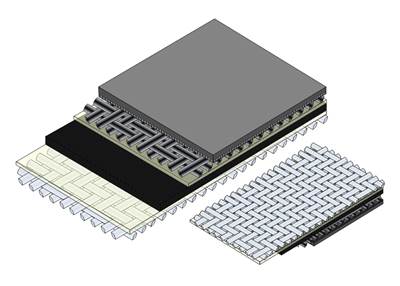

Read MoreMove over honeycomb, thermoplastic sandwich is commercialized as DYNATECH

PEI foam core/skin sandwich panels claim to save up to 40 percent weight and 30 percent cost in rail and aircraft interiors vs. honeycomb.

Read MoreProcessing within the PUR cure window

Composite Spray Molding enables volume production of fiber-reinforced polyurethane sandwich structures for auto interiors. Are Class A exterior parts next?

Read MoreMove over steel — Aluminum is now the target

Dale Brosius, a consultant and president of Quickstep Composites (Dayton, Ohio), observes that chasing aluminum as a competitor is a much easier task than chasing steel — if the composites industry can meet cost and volume requirements.

Read MoreBusiness and busy-ness

CT editor-in-chief Jeff Sloan returns for JEC Europe 2014 in Paris with observations about several intriguing composites industry trends.

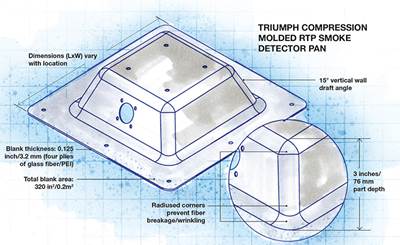

Read MoreCompression molding mass out of aircraft interiors

Continuous carbon fiber-reinforced thermoplastic lightweights smoke detector pan and slashes production cycle time.

Read MoreLFI process: Molding strong and attractive spa enclosures

Dynasty Spas (Athens, Tenn.) finds a composite alternative to wood hot tub surrounds in a polyurethane (PU)-based long fiber injection (LFI) solution implemented by Romeo RIM Inc. (Romeo, Mich.).

Read MoreFaster cycle, better surface: Out of the autoclave

GM is first automaker to use Class A CFRP parts from new pressure-press technology.

Read MorePress-molding method emulates autoclave

Rubber tool insert avoids consolidation pressure “dead zones” and slashes cost.

Read MoreClass A CFRP body panels: Six-minute cure

Gurit CBS-based laminate/process combo mints parts with twice the thermal performance in one-sixth the time.

Read More