Aerospace

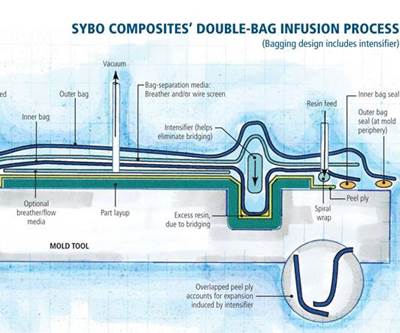

Double-bag infusion: Thickness gradient and pressure

Cliff Walker (Vacmobiles, Auckland, New Zealand), explains how the large pressure changes during infusion result in laminate compression and thickness variations across the part.

Read MoreDouble-bag infusion: 70% fiber volume?

A double vacuum-bag system and tight process control enable repeatable fiber volumes of 60 to 70 percent and improves consistency of infused laminates.

Read MoreInternational Building Code: Meeting requirements for interior composites

How to produce FRP parts that can meet International Building Code flame-spread and smoke-obscuration specifications.

Read MoreUnmanned Systems North America 2010

Growing trade event underscores composites’ continuing vital role in unmanned systems for aviation and marine applications.

Read MoreShape shifters: The molecular basics

The key to SMP shape change is the fact that an SMP can exhibit a radical transformation from a rigid polymer to a malleable elastomer and back again.

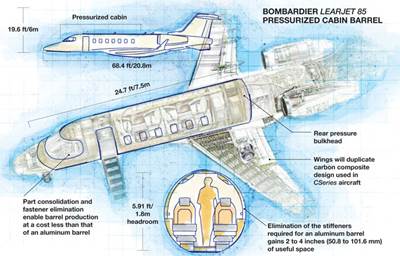

Read MoreLearjet 85 composite pressurized cabin a cost cutter

Single-piece carbon fiber composite structure selected over multipiece aluminum fuselage barrel section in new bizjet design.

Read MoreHigh-Performance Resins 2010 Highlights

Inaugural conference for the advanced resins research crowd updates formulators and processors on the latest developments.

Read MoreFuture multifunctional structures: Composites needed

Barton Bennett (Odyssian Technology, South Bend, Ind.) discusses multifunctional systems that will soon integrate composite structures with sensors, mechanisms and subsystems.

Read MoreSQRTM enables net-shape parts

New out-of-autoclave process combines resin transfer molding with prepregs for complex helicopter part prototype.

Read More