ThermHex Waben GmbH

Merseburger Str. 235

Halle (Saale), 06130 DE

49 (0) 345 131627 0

info@thermhex.com

IS THIS YOUR COMPANY?

As Seen On ÂÌñÏ×ÆÞ

Editorial, News, and Products

-

HyWaSand demonstrates large-series production potential for automotive TP sandwich components

Storage compartment flap for truck interior produced via fully automated continuous fiber thermoplastic sandwich molding technology shows suitability for series manufacture.

-

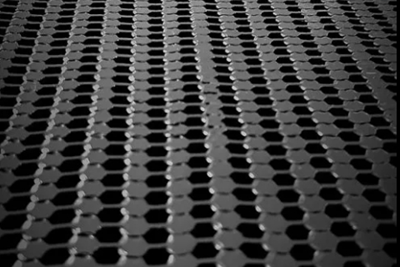

Thermoplastic honeycomb, lightweight solar modules demonstrate sustainability

CAMX 2023: Together, EconCore and ThermHex are providing a first look at new product variations for additional lightweight opportunities, including high-performance thermoplastic cores and solar panels with a honeycomb structure.

-

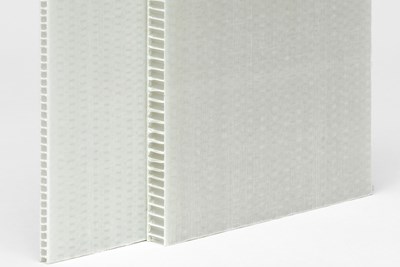

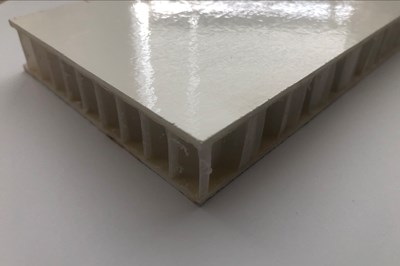

ThermHex Waben highlights thermoplastic honeycomb panels

Economically produced composite sandwich panels are sustainable while maintaining high mechanical performance and surface quality, driving them into new market applications.

-

Global experts present latest developments at Composite Sandwich Conference in May

The CSC 2022 conference, jointly organized by Thermhex and Fraunhofer IMWS, enabled a productive exchange of information about cost-efficient composite sandwich structures and automated processing methods.

-

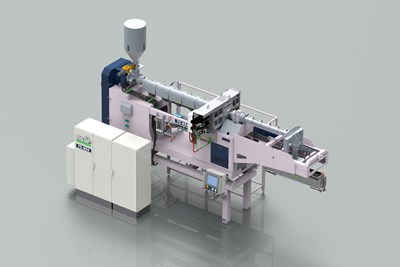

EconCore, ThermHex Waben optimize honeycomb core production

An investment in additional MEAF 75-H34 extruders reduce energy consumption in honeycomb production by up to 65% and double capacity.

-

ThermHex acknowledged as a TOP 100 innovator in Germany

Out of 436 participants, the honeycomb core specialist has been honored for its excellence in driving forward production process innovation.

-

ThermHex receives quality, environmental management certification

Thermoplastic honeycomb core producer earns ISO 9001 and ISO 14001 national and international management system standards.

-

ThermHex, EconCore invest in automated production for PP honeycomb sandwich, recycled PET products

Targeting recycled and high-performance thermoplastic options, automated R&D lines increase volume and speed for honeycomb, sandwich panel and finished part production.

-

ThermHex, Brixtone complete honeycomb core panel production for 400 commercial vans

Cargopan wall panels incorporate ThermHex polypropylene honeycomb core for increased robustness damage resistance, waterproofing and a tripled lifespan.

-

ThermHex reports a €1 million capital increase

The business growth follows new investments to further optimize and expand ThermHex’s digitalization of its honeycomb core production processes.

-

ThermHex honeycomb core insulates 2,000 camper van elevated roofs

Polypropylene honeycomb panels improve the camper vans’ fuel efficiency with 80% less weight, full functionality when wet and a stable foundation.

-

ThermHex launches new honeycomb core, aims for carbon neutrality

Retaining a Class A surface, the newest core product was produced via electricity from renewable energy sources. With several notable achievements, ThermHex is also looking for distributors.

-

Polypropylene honeycomb lightens, strengthens automotive panels

Polypropylene honeycomb cores from ThermHex are used by Brazilian OEM DPA Moldados to make the trunk floor of the Hyundai Creta ix25.

-

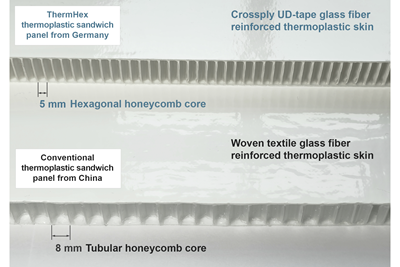

ThermHex unveils new Organosandwich material

The thermoplastic sandwich material is said to offer a range of possible applications in the automotive sector, offering weight savings of over 80% compared to a monolithic design.