SAM XL

Rotterdamseweg 382C

Delft, Zuid-Holland 2629 HG NL

31 (0)15 278 6214

communications.samxl@tudelft.nl

IS THIS YOUR COMPANY?

As Seen On ÂÌñÏ×ÆÞ

Editorial, News, and Products

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

-

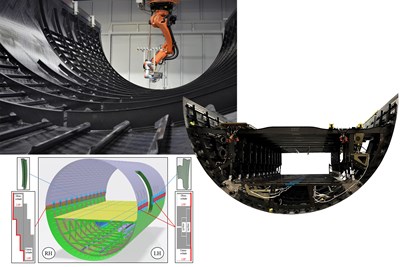

SAM XL demonstrates closed-loop digital methodologies via full-size aerocomposite parts development

PeneloPe Project’s modular, zero-defect manufacturing deliverables are being highlighted in an upcoming video that demonstrates the resulting aerospace pilot line’s feasibility.

-

CEAD grows large-scale 3D printing presence with new facility opening

From garage startup to global 3D printing company, CEAD’s 3,000-square-meter facility, featuring Flexbot, extruders and more, opens up the potential for new R&D, partner collaborations and future company growth.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Airborne delivers composite upper stage tank for EU ENVOL project

Nine-member consortium targets development of low-cost, green vertical orbital launcher with manufacture of an ultra-lightweight composite tank design in an automated manufacturing environment.

-

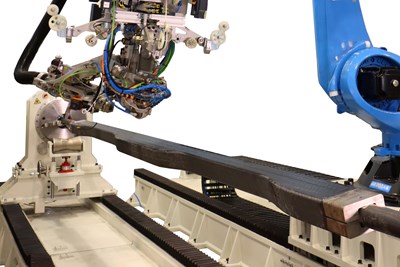

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

-

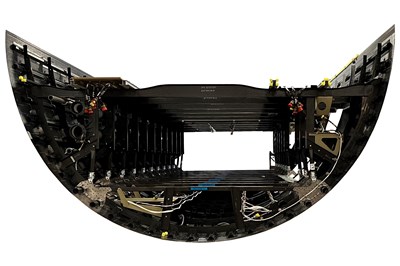

STUNNING project completes lower half of MFFD

Clean Sky project has delivered the 8 × 4 meter welded aerostructure component, aided by advanced thermoplastic composite technologies and smart robotics.

-

Demonstrating composite LH2 tanks for commercial aircraft

Toray Advanced Composites and NLR discuss the Netherlands consortium and its 4-year project to build demonstrator liquid hydrogen tanks, focusing on thermoset and thermoplastic composites.

-

Thermoplastic composites welding: Process control, certification, crack arresters and surface prep

More widespread use of welded composite structures within a decade? Yes, but further developments are needed.

-

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

-

Will the Airbus-CFM H2 flight demonstrator use metal or composite tanks?

The Airbus A380 testbed will fly in 2026 with four 100-kilogram liquid hydrogen tanks — metal and composites are being developed via Airbus ZEROe Development Centres — with multiple other programs to develop composite H2 tanks for civil aviation that were begun in 2021.

-

Addcomposites adds tape winding to Finland facility for pilot trials

The new capability, which enhances the available level of design freedom, was added to encourage manufacturers to develop new innovations using tape winding.

-

Toray Advanced Composites leads research consortium for LH2 composite tank developments

Dutch industries, institutes join Toray Advanced Composites for the manufacture of a civil aviation-focused lightweight composite tank which can withstand very low temperatures.

-

SAM|XL receives grant for composites research towards sustainable aviation

Jointly with TU Delft Faculty of Aerospace Engineering, the SAM|XL field lab will receive €4.9 million for projects in liquid hydrogen composite tanks, thermoplastic composite aerostructures and smart maintenance and repair.