SAERTEX USA LLC

12200-A Mt. Holly-Huntersville Rd.

Huntersville, NC 28078 US

704-464-5998

info@saertex.com

CONNECT

About SAERTEX USA LLC

SAERTEX USA develops and manufacturers customized non-crimp fabrics and other materials used for composite applications in the wind energy, marine, aerospace, automotive, sports and leisure, railway, civil infrastructure, and numerous other technical markets throughout the world.

IS THIS YOUR COMPANY?

As Seen On ÂÌñÏ×ÆÞ

SAERTEX USA LLC Supplies the Following Products

- Aramid

- Basalt

- Carbon

- Carbon/Glass Hybrid

- E-Glass

- Other Core Materials

Editorial, News, and Products

-

Basic, multiaxial composite material offerings balance processing and performance

CAMX 2025: Saertex USA is a domestic materials partner offering reliable high-quality composite reinforcements and local service, from 150-inch-wide multiaxial fabrics with Chop to comprehensive material ranges.

-

IACMI: Driving innovation in the advanced composites industry

Since its start in 2015, the Institute for Advanced Composites Manufacturing Innovation (IACMI) has come a long way in its mission of advancing composites innovation. CTO Uday Vaidya reflects on the past five years.

-

UV-curing grows composites market share

Established and flourishing in the underground pipe relining arena, UV-curable resins are finding new applications in other out-of-the-way places.

-

Why South Carolina? Why now?

CW guest columnist Tom Lemire (T.F. Lemire Consulting Inc., Irvine, CA, US), comments on the aerospace industry's current attraction to this particular spot on the US map and wonders if it's the beginning of a trend.

-

Moldmaker bypasses patterns for high-tech production catamarans

Direct-to-milled-tool process simplifies large deck mold development.

-

CAMX 2014 exhibit previews, part 2

With CAMX 2014 less than a week away (Oct. 13-16, Orlando, Fla.), ÂÌñÏ×ÆÞ offers a final glimpse of some of the products, technologies and services that you will find in booths in the Exhibit Hall. During the show, we'll keep you informed and up-to-date with the CAMX Show Daily, which will be distributed Tuesday, Wednesday and Thursday at the show. Safe travels to Orlando and we look forward to seeing you at the conference and trade show.

-

VX Aerospace: Small company, big performance

Innovative design, OOA manufacturing and C-PLY laminate construction produce “big fabricator” aerostructures in fewer steps at low cost.

-

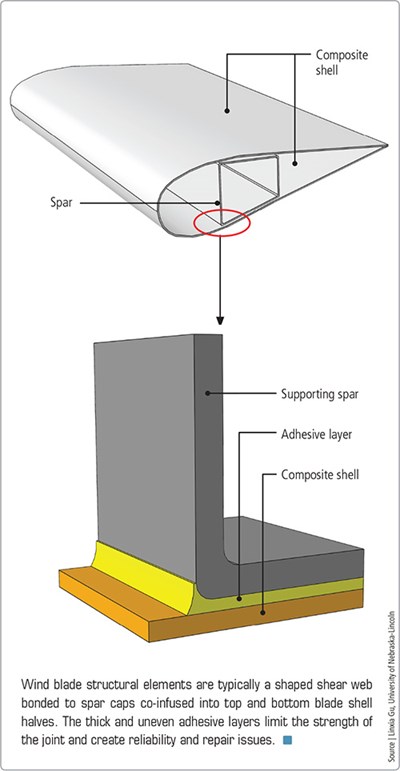

Wind blades: Pi preforms increase shear web failure load

Easily coinfused structural joint increases ultimate strength and fatigue life, offering solutions for designers as blades get longer and move offshore.

-

Bio-composites update: Beyond eco-branding

No longer dependent only on their green credentials, some suppliers of bio-based fibers and resins are competing on price and performance.

-

Aiming infusion at the application

With so many process variables to play with, how do you know which new solutions that promise better, faster infusion are right for your application?

-

SPE ACCE 2011: Growing again

The Society of Plastics Engineers’ 11th conference on automotive composites fields a top slate of speakers and attracts its largest crowd.

-

PRSEUS preform for pressurized cabin walls

Over the next few years, NASA and The Boeing Co. (Chicago, Ill.) will build larger and more elaborate pressurized passenger cabin structures for future blended-wing airliners.

-

SAMPE 2011 Long Beach Product Showcase

Huge show, huge new product offerings … huge success.

-

Composites 2010 Product Showcase

The ACMA’s Las Vegas exhibition reflected an industry in recovery.

-

A400M cargo door: Out of the autoclave

This structural military airframe part is the largest made to date via the vacuum-assisted resin infusion process.

-

JEC Composites 2009 showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.

-

Team-built bus body bests all

OEM meets tight development schedule on superlight multipart molded shell to offset propulsion system weight in fuel cell-powered transit bus.

-

Fabric Forms Get Sophisticated

Closed molding applications and demand for greater design flexibility are driving fabric suppliers to create a variety of products that mix and match fibers, fiber forms, core and resin.

-

Autoclave Quality Outside The Autoclave?

Pioneers of out-of-autoclave processing in aerospace applications answer a qualified but enthusiastic Yes!

-

Fiberglass multiaxials reinforce their market share

Technological and market forces feed growing use of multiaxial nonwoven fiberglass fabrics and spur diversified product offerings.

-

Anisotropic wind blade design expected to reduce wind-energy costs

Deliberately unbalanced laminate produces smoother power input from adaptive wind blades

-

Racing Veteran Fine-tunes Classic Competitive Concept

Hand layup of reinforced epoxy yields hybrid luxury powerboat/offshore racer.

-

Carbon fiber/epoxy wheels developed to replace metal wheels on large freight trailers

Semi-trailers roll lighter with Prins Dokkum's carbon fiber Dynawheels.

-

Carbon/glass hybrids used in composite wind turbine rotor blade design

As turbine blades grow to greater lengths, composite blade manufacturers take a long look at carbon/glass hybrids.

-

Europe's Infusion Pioneer Simplifies Process With Bottom Up Approach

Yacht builder's computer-designed method yields vacuum infusion without technical confusion.

-

An Elegant Solution For A Big Composite Part

The rear pressure bulkhead for the Airbus A380 employs resin film infusion.