National Composite Center

2000 Composite Dr.

Kettering, OH 45420 US

937-297-9450

lnovelli@compositecenter.org

About National Composite Center

IS THIS YOUR COMPANY?

As Seen On ÂĚñĎ×ĆŢ

National Composite Center Supplies the Following Products

- Vacuum-Assisted Resin Transfer Molding (VARTM)

- Automated Fiber Placement

- Clay (Modeling)

- Coating & Painting

- Composite, Other

- Composites - Materials & Product Testing & Analysis Equipment

- Composites Materials

- Composites Process Development

- Compression Molding

- Fiberglass Composite

- Filament Winding

- Hand Layup

- Inspection Services

- Preforms, Unimpregnated

- Pressure Forming

- Prototype

- Prototyping

- Pullwinding

- Pultrusion

- Reaction Injection Molding (RIM)

- Resin Transfer Molding (RTM)

- Sprayup

- Structural Reaction Injection Molding (SRIM)

- Training & Workforce Development Services/Software

Editorial, News, and Products

-

U.K. Carbon Fibre Development location is revealed

The NCC has confirmed its location in North West England at Cygnet Texkimp’s site. Full operation is expected by spring 2026.

-

NCC backs U.K. Industrial Strategy for industry innovation scale-up

The U.K. government’s recently published economic approach aims to remove barriers and set a clear path toward growth opportunities in advanced manufacturing, aerospace, clean energy, defense and AI.

-

Natural fiber composite wheelchair seat design aims for sustainable mobility

The National Composites Centre and Motivation provide an easily manufactured, locally sourced mobility solution for disabled people in developing countries.

-

NCC launches new online composites training platform

Suite of affordable introductory and practical and theory based, in-person courses taught by composites experts available to users at any location and organization.

-

Carbon ThreeSixty joins NCC as SME Affiliate Scheme member

Program members gain access to NCC knowledge, training and networking events for innovation, growth and investment in composites.

-

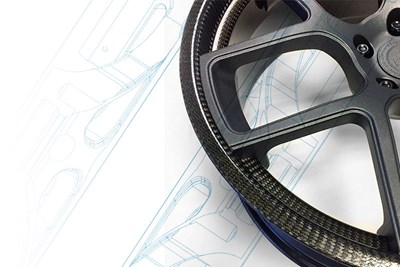

Carbon ThreeSixty, Leonardo, NCC all-composite helicopter wheel project takes off

The 18-month project will design, develop and manufacture 12 fully tested ultra-low mass, robust, proof-of-concept CFRP wheels for rotary wing aircraft.

-

NCC, Dstl facilitate R&D program for combat aircraft composite structures

The partnership invites organizations to pitch their most innovative ideas and capabilities to influence the direction of the ADCoSCA research program.

-

Innovate UK grants NCC £355k to help achieve net zero future

Funding will investigate how composite materials can best be used in final products, mitigation of their environmental impact and overall sustainability.

-

U.K. launches initiative for recyclable wind turbine blade technologies

The SusWIND initiative, addressing the recyclability and future development of composite wind turbine blades, will be delivered in three developments.

-

SAMPE 2011 Long Beach Product Showcase

Huge show, huge new product offerings … huge success.

-

Bio-based fillers: Reducing SMC mass

The Bio-Lite Technical Center of Excellence at the National Composites Center (Dayton, Ohio) is developing sheet molding compound (SMC) recipes capable of yielding finished parts with specific gravity as low as 1.2.

-

Optimizing the performance of C/C brakes

Renowned architect Mies van der Rohe once observed about the nuances of building design, “God is in the details. ” The same could be said for the manufacture of carbon/carbon (C/C) brakes.

-

Resin systems update: The greening of thermosets

Thermoset resin formulators seek environmental benefits as customers demand reduced cost and increased performance.

-

Integrated drop-in-place superstructure the solution for Eight Mile Bridge

Based on the successful performance of previous composite bridge decks installed in Hamilton County, Ohio, highway engineers recently took a bold step, specifying an integrated composite bridge superstructure — that is, deck and support beams together in one unit — to replace a deficient span known as Eight Mile Bridge.

-

High-Volume Preforming for Automotive Application

More than a dozen parts for four Aston Martin models are mass produced in France using Ford Motor Co.'s optimized Programmable Preforming Process and resin transfer molding.

-

Building Bridges to Bridge and Building Rehab Markets

Despite a lack of standardization and education in the civil construction sector, these innovators use carbon and steel fibers to reinforce the business case for composites.

-

Engineering Insights: Pedestrian Bridge Makes Case for Composites

Infusion molded deck incorporates high-performance core, which facilitates fast processing.

-

Rapid Fiber Preforming On A Large Scale

A proven alternative to open molding of big parts.

-

PZTs energize active composites

NCC/ACI partnership to commercialize flexible lead zirconate titanate piezoelectric fibers in self-powered and "smart" composite products.