Kuka Robotics Corporation

51870 Shelby Pkwy.

Shelby Township, MI 48315 US

800-459-6691 | 586-873-5852

kukainfo@kukarobotics.com

CONNECT

About Kuka Robotics Corporation

IS THIS YOUR COMPANY?

As Seen On ÂĚñĎ×ĆŢ

Kuka Robotics Corporation Supplies the Following Products

- Assembly & Testing Automation

- Automated for Material Joining

- Automation/Systems Integration

- Directed Energy Deposition

- Engineering Analysis & Simulation

- Laser Cutting Systems

- Material Forming & Fabricating Automation

- Material Removal Automation

- Robot Controllers

- Robot Tooling/Grippers

- Robots

- Special Purpose Forming & Fabricating Equipment

- Waterjet Cutting Machines

- Welding & Related Equipment

Editorial, News, and Products

-

Putting next-generation composite materials, processes to the test

Research at Faserinstitut Bremen’s ECOMAT site, alongside industry partners, aims to enable sustainable, aerospace-focused composites — including thermoplastic welding and cryogenic material testing.

-

Conbility delivers laser-safe TPC winding cell to FIBRE Bremen

Turnkey winding system will support the German institute’s aerospace R&D efforts, including LATW, tape placement with in situ consolidation and a later thermoset upgrade.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

AI-powered robotic solutions support high-mix manufacturing

AI startup offers automation innovations for high-mix, high-variability, manual surface finishing applications.

-

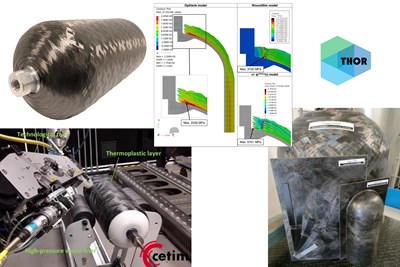

Update: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

-

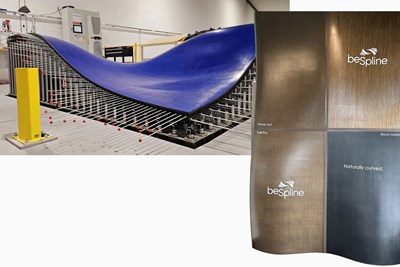

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Urban furniture project demonstrates green potential for composite 3D printing and recycled materials

Large-format AM specialist Caracol and partners designed custom, 3D-printed outdoor furniture with glass fiber-reinforced recycled polypropylene, and conducted an LCA to evaluate and improve the process.

-

DLR develops safe, flexible workspaces for robot-assisted manual draping

The EU project Drapebot works on new ways of collaborating with industrial robots for manual CFRP preforming for large aircraft structural parts.

-

Machina Labs unveils Machina Deployable System for agile manufacturing

Portable system combines AI and robotics for the forming and cutting of custom composite and metal parts.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Robotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

-

Plant tour: Avel Robotics, Lorient, France

From AFP hydrofoils to more efficient aircraft parts, Avel uses digital design, multiprocess production and a rule-breaking approach for complex 4D composites.

-

CFRTP upper stage propellant tank

PROCOMP uses in-situ consolidation AFP and ultrasonic welding to demonstrate lightweight, novel tank design.

-

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

-

Automated filament winding system increases throughput, reduces manual labor for pressurized well tank production

For its new line of composite well water tanks, Amtrol worked with Roth Composite Machinery on an automated process for faster, more easily tracked production.

-

Composites enable epic interior for Museum of the Future

For this one-of-a-kind lobby, AFI pioneered digital, reconfigurable molds to achieve organic-shaped, multifunctional panels and stairwell cladding.

-

Advanced Fiberglass Industries: Composites enable innovation

With decades of composites design and fabrication experience, Dubai-based AFI turns problems into solutions.

-

Plant tour: ÉireComposites, Galway, Ireland

An in-house testing business and R&D focus has led to innovative materials use and projects in a range of markets, from civil aerospace to renewable energy to marine.

-

Low-void, large-scale, high-volume 3D-printed composites

Among its many composites-related projects, Oak Ridge National Laboratory recently installed its first AMCM test cell, combining extrusion with compression molding for fast, low-void, low-porosity thermoplastic composite parts.

-

Plant tour: National Institute for Aviation Research, Wichita, Kan., U.S.

NIAR, located at Wichita State University in the heart of the American aerospace manufacturing industry, has evolved to become a premier hub of teaching, R&D, creativity and innovation.

-

Air-cushion barge serves ice, shallow water operations with infused carbon fiber propellor ducts

Four composite propellor ducts supplied by A C Marine & Composite drive forward the steel-built hybrid hovercraft design to provide essential services year-round in the North Caspian Sea.

-

Orbital Composites installs robotic manufacturing system at NREL for wind turbine blade research

Customized, automated platform expands NREL’s capabilities for researching blade-finishing technologies and serves as Orbital’s sounding board for applicable composites solutions in aerospace, space and infrastructure.

-

CosiMo: Smart thermoplastic RTM process demonstrated for battery box cover challenge simulator

Project uses network of DEA, temperature/pressure and ultrasonic sensors plus digital simulation and AI modeling to monitor and optimize injection of caprolactam into complex glass fiber preform and in-situ polymerization of PA6.

-

DLR Institute of Structures and Design increases maturity of thermoplastic composite fuselage structures

Project with Airbus demonstrates OOA co-consolidated stringer-stiffened skin with resistance welded frame and cleats.

-

CAMX 2021 exhibit preview: Carbon Axis

Carbon Axis showcases compact AFP solutions for the preforming of small parts with the XCell, XPlace mk2 and IdeaLab.

-

Solution-based digital composites fabrication

MIT evolves liquid biomaterials into a new approach for sustainable engineered composite structures.

-

Additive manufacturing adds versatility to large marine structures

Dive Technologies and Moi Composites are among those extending composite 3D printing’s design flexibility past prototyping and into customizable end-use parts.

-

UT Austin installs Addcomposites AFP-XS with laser for in-situ consolidation of thermoplastic composites

Modular, compact and versatile AFP system to help University of Texas explore thermoplastic composites technologies.

-

Large-scale, robotic-mounted 3D printer aims to expand AM size limits

Italy-based Caracol has developed an extrusion-based, robot-mounted 3D printer to scale up printing capabilities for high-performance aerospace tooling and industrial parts.

-

MAMBO tests the waters for 3D printing large marine structures

With its MAMBO boat, Moi Composites demonstrates use of its continuous fiber 3D printing technology for customized, automated production for the boating industry.

-

Plant Tour: RUAG Space, Decatur, Alabama, U.S.

Out-of-autoclave composites manufacturing facility comes of age with first U.S.-made composite structures for the Atlas V launcher, and qualification parts for the Vulcan.

-

Plug-and-produce AFP system installed in one day and debuts at composites automation center

Addcomposites completes installations of its AFP-XS toolhead at KUKA Finland and SAM|XL in Netherlands.

-

High-speed, high-rate thermoplastic composites manufacturing

A novel process from SABIC and Airborne promises high-speed, high-rate production of thermoplastic composite laminates for mainstream manufacturing and a variety of applications.

-

GKN Aerospace breaks ground on UK Global Technology Centre

Twenty-five partners will also collaborate on the center, which will focus on research for additive manufacturing and advanced composites for aircraft.

-

Plant Tour: STELIA Aerospace, Méaulte, France

Supplier of Airbus fuselage sections pushes boundaries of hybrid aerostructures production, assembly and thermoplastic composites.

-

Spar forming simplified

Adapting its Automated Stiffener Forming (ASF) technology to build spars directly in female molds, Northrop Grumman Innovation Systems anticipates dramatic drops in cycle time and manufacturing cost.

-

JEC World 2019 preview: SABIC

SABIC (Pittsfield, Mass., U.S., 6/P12) is highlighting the progress of its Digital Composites Manufacturing line, an automated digital systems for rapid, large-scale laminate manufacturing, via a 360-degree virtual reality experience.

-

Thermoplastic overmolded thermosets, 2-minute cycle, one cell

Adhesive-free, functionalized hybrid composites enabled by industry-first, integrated molding cell.

-

GKN Fokker to implement automated kitting solution from Airborne

The automated kitting solution is said to reduce costs by saving man-hours and material scrap, and it enabling a flexible and digital workflow.

-

Continuous Fiber Manufacturing (CFM) with moi composites

Continuous fiber 3D printing using epoxy, vinylester and acrylic with continuous glass, carbon, basalt and other fibers, including deposition along nonlinear curves, is only the beginning.

-

Drones: Composite UAVs take flight

First seen in defense applications, unpiloted aircraft development is surging in the commercial world, enabled by a host of new material, process and assembly technologies.

-

Automated manufacturing solutions from Airborne

I had the chance recently to interview Marcus Kremers, chief technology officer of Airborne International (The Hague, Netherlands), who told me about his company’s growing smart automation initiatives for its customers.

-

CW Plant Tour: Composite Technology Center, Stade, Germany

A cornerstone of Germany’s CFK Valley, CTC pushes composites forward via automation, recycling, digital thread-based manufacturing and more.

-

BMW 7 Series Plant: Dingolfing, Germany

Via four different manufacturing methods, CFRP goes mainstream in automated multi-material BIW and assembly operations at BMW’s busiest plant.

-

Automation: Robots taking off in commercial aircraft

Will this affordable and versatile class of multiaxis manufacturing hardware and software drivers enable airframers to reduce costs and speed deliveries?

-

NASA/Boeing composite launch vehicle fuel tank scores firsts

Subscale 5.5m-diameter cryogenic tank demonstrator with innovative fluted-core skirt is formed via robotic AFP and cured out of the autoclave.

-

Thermoplastic composites technology: A view from Europe

For this Dutch consortium, bringing the manufacturability of thermoplastic materials to maturity is the goal in concert with OEMs, materials and equipment supplier members.

-

Plant tour: ATK Aerospace Structures, Clearfield, Utah, U.S.

High-volume, high-precision fiber and tape placement for the aerospace industry are among many specialties for this composites manufacturing behemoth.

-

Main landing gear doors designed for all contingencies

For the Airbus XWB airliner, they must meet strict structural, aerodynamic, emergency and aesthetic requirements.

-

Nondestructive inspection: Better, faster and cheaper

Faced with new time and cost pressures, NDI system suppliers are integrating inspection with manufacturing to reduce its share in part cost and cycle time.

-

Structural preform technologies emerge from the shadows

Not yet in full production, with one exception, all are aimed at accelerating composite part manufacture at fast automotive rates.

-

Integrated, optimized aircraft door

This composites manufacturer is betting its one-piece 3-D preform and RTM process will trim weight from today’s fastener-intensive “black aluminum” aircraft doors.