Hexagon Manufacturing Intelligence

250 Circuit Dr.

North Kingstown, RI 02852 US

800-343-7933 | 401-886-2000

marketing.na.mi@hexagon.com

CONNECT

About Hexagon Manufacturing Intelligence

IS THIS YOUR COMPANY?

As Seen On ÂÌñÏ×ÆÞ

Hexagon Manufacturing Intelligence Supplies the Following Products

- Comparators, Optical & Other

- Coordinate Measuring Machine (CMM) Software

- Coordinate Measuring Machines

- Digitizing/Scanning Equipment

- Gear Inspection Equipment

- Inspection/Measurement Services

- Job & File Management Software

- Laser Measurement Systems

- Modeling/Simulation/Virtual Testing Software

- Part Design Software

- Probes, Electromechanical

- Scanning & Metrology Services

- Vision Systems

Editorial, News, and Products

-

Composites business growth through diversification, innovation

San Diego-based 2024 Top Shops qualifier Rock West Composites gives an overview of its relentless commitment to improvement, including its composite capabilities and its role as a trusted player in the space market.

-

Portable Hexagon Leica ATS800 achieves rapid measurement of large, intricate components

The Leica Absolute Tracker delivers accurate measurement of key features from a distance, using direct scanning to meet the demands of inspection and alignment in aerospace and other large-scale manufacturing sectors.

-

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

-

JEC World 2023 preview

JEC World is the composites industry’s largest trade event, featuring exhibits, presentations and specialized pavilions covering the entire composites industry supply chain.

-

Rockwood Composites to quadruple capacity with new U.K. facility, subsidiary in Morocco

U.K. composite components manufacture will transition from 5,000 to more than 30,000 square meters of facility space, with additional growth in end market services and skilled engineers.

-

CAMX 2022 exhibit preview: Hexagon

Hexagon’s Digimat + Volume Graphics workflow interface delivers a robust connection between process, material and performance, enabling new advanced materials exploration.

-

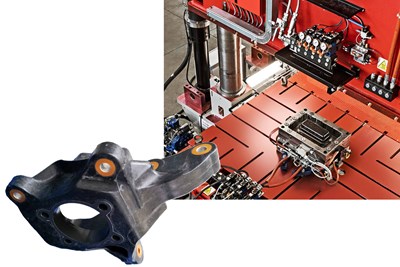

A digital twin to validate SMC performance in suspension structures

High-fidelity, anisotropic behavior material card, integrated with process simulation, structural FEA and validated with CT and physical tests enables optimization proven in award-winning SMC suspension knuckle.

-

Price, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

-

SAMPE North America seeks active volunteers for technical committees

The global professional member society encourages SAMPE members and non-members who are interested in actively engaging, sharing expertise and networking to develop advanced technological solutions.

-

German UniFix project develops mobile holding fixture to enhance production efficiency of large CFRP structures

Fraunhofer IFAM and Airbus Operations in Stade demonstrate reduced manual handling and non-productive time in flow-oriented manufacturing of vertical tail plane.

-

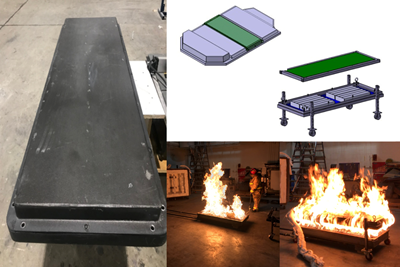

SuCoHS project: Advancing composite solutions for parts with high thermal and mechanical loads

New materials, structural concepts and manufacturing using sensors for composites that resist fire, temperature and loads while providing weight and cost savings versus metals.

-

Upcoming CW Tech Days webinar assesses virtual testing, qualification for composite structures

CW Tech Days: Design, Simulation and Testing Technologies for Next-Gen Composite Structures will be held April 21, 2022, and will assess design, simulation, failure analysis, digital twins and more.

-

Plant tour: Qarbon Aerospace, Milledgeville, Ga. and Red Oak, Texas

Veteran aerostructures Tier 1 transforms into 21st century leader in thermoplastic composites and multiple new markets.

-

Predicting and mitigating failure in composite parts

Understanding the complexity of composites manufacturing resides in studying the design challenges inherent to fabrication, as much as the physics aspect. To serve this effort, CW introduces a new column, “Predicting Failure.”

-

Plant tour: Victrex Composites Solutions, Bristol, Rhode Island, U.S.

De-risking thermoplastic composites at industrial scale via hybrid overmolding.

-

How to validate 3D-printed composite part performance

Integrated Computational Materials Engineering (ICME) workflow simulates composite material performance to speed development, optimize performance and reduce costs for a redesigned 3D-printed CFRP bracket.

-

The democratization of composites is reconfiguring supply chains

New robotic and digital technologies are enabling advanced in-house capabilities for small companies and innovative suppliers willing to embrace the move toward more affordable, sustainable composites.

-

Hexagon, Authentise end-to-end software platform streamlines AM workflow

Solution integrates shop floor data with data intelligence to orchestrate consistent quality through concept to part for AM industrialization.

-

Hexagon REcreate reverse engineering software removes workflow complexity

Simplified reverse engineering processes provides a single working environment from scan to manufacturable CAD model.

-

Automated aerocomposites production: Liquid molding or welded thermoplastic?

Two materials and process approaches are demonstrated for CFRP bulkhead production.

-

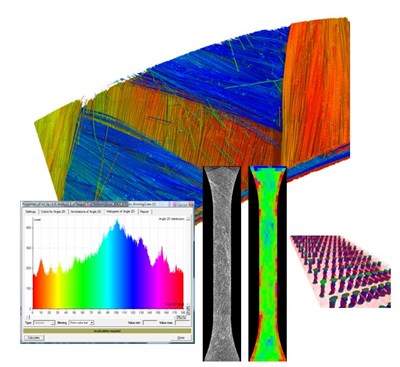

Hexagon vision inspection eliminates manual inspection process

According to AMRC’s case study, Hexagon’s composite inspection technology uses 3D modeling to scan and map fiber orientation data, generating a 3D profile of the part being inspected.

-

C-FREX exoskeleton depends on CFRP for unpowered movement

C-FREX uses a novel design and CFRP to overcome the heaviness and weakness of metallic exoskeletons.

-

Exact Metrology presents RS-SQUARED area scanner

Manufactured by Hexagon, the 3D white light scanner is designed for high-speed, portable scanning of parts and surfaces.

-

Plug-and-produce AFP system installed in one day and debuts at composites automation center

Addcomposites completes installations of its AFP-XS toolhead at KUKA Finland and SAM|XL in Netherlands.

-

CAD viewer software updates simplify printing, two-way file flow

The 2020.1 software release for Hexagon’s WORKXPLORE includes enhancements for specific simulation import, additional reader translators and client viewer measurements.

-

New Digimat 2019.1 release enables smarter fiber-reinforced composite design values, allowables and crash modeling

Upgrades include high fiber content virtual test with 10-100 times faster analyses and progressive damage analysis using the Camanho method.

-

Airbus selects MSC Software's MaterialCenter platform

The software platform will enable Airbus to more easily manage material workflow from one database across divisions.

-

DSM 3D printing acceleration program accepting applications

The I AM Tomorrow Challenge is a ten-week program designed to help startup companies launch or mature their additive manufacturing innovations.

-

Automated, in-situ inspection a necessity for next-gen aerospace

Inline inspection technologies continue to evolve with the aim of providing faster and more accurate part inspection.

-

Plant Tour: STELIA Aerospace, Méaulte, France

Supplier of Airbus fuselage sections pushes boundaries of hybrid aerostructures production, assembly and thermoplastic composites.

-

Smarter, integrated data for ATL/AFP

More than helping to eliminate dry runs and costly errors, AFP/ATL software is beginning to benefit the whole product lifecycle through the interconnectedness of the digital thread.

-

Plant tour: Meggitt San Diego, CA, US

This aerospace and defense fabricator upgrades to a larger facility and gets, in the process, a chance to rethink and optimize material, people and process flow.

-

Hexagon unveils production software business

Vero Software, FASys and SPRING Technologies have been combined under the Hexagon brand.

-

Improving composites processing with automated inspection, Part II

Three additional inspection equipment providers describe their development of inline production quality-control systems.

-

Classic Reflections Coachworks: Tacoma, WA, US

They didn’t invent the wheel, but they take pride in reinventing — via high-quality CFRP and precision manufacturing — newer-model Corvettes with exteriors inspired by iconic Corvette stylings from this classic’s early days.