Accudyne Systems Inc.

210 Executive Drive

Suite 5

Newark, DE 19702 US

302-369-5390

info@accudyne.com

About Accudyne Systems Inc.

IS THIS YOUR COMPANY?

As Seen On ┬╠├▒¤ÎĂŮ

Accudyne Systems Inc. Supplies the Following Products

- Automated Fiber Placement Systems

- Automated Tape Laying Systems

- Bladder Molding Equipment (Formerly Pressure Bag)

- Composites Controls & Software

- Continuous Laminating Machines

- Filament Winding Machines & Controls

- Impregnation Lines

- Other Primary Manufacturing Equipment

- Robots

- Roll-Wrapping Machines (Not Tables)

- Splicing Devices

- Spray Booths

- Tensioning Equipment

- Vacuum Formers

- Vacuum-Assisted Resin Transfer Molding Equipment (VARTM)

Editorial, News, and Products

-

Custom equipment manufacturer accentuates multidisciplinary design, engineering approach

CAMX 2025: From supporting civilian and DOD programs to everyday customer needs, Accudyne Systems strives to deliver production improvements over existing composites manufacturing systems.

-

The AAMMC Tech Hub: Ramping U.S. production of large thermoplastic composite aerostructures

CW talks with Syensqo, Spirit AeroSystems and other consortia members about current funding, specification of the next world’s largest press, organizational structure and projects to support U.S. companies in the race to deliver >40,000 sustainable and efficient aircraft over the next 20 years.

-

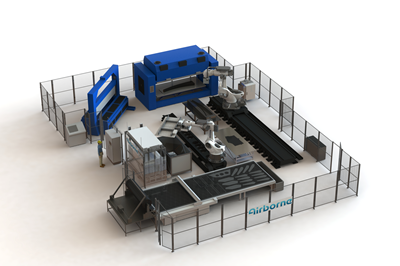

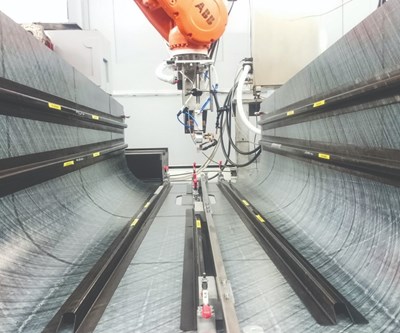

Modular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

-

Airborne to deliver automated preforming line to GKN Aerospace

Automated cell combines ply placement, preform trimming, a ply cutter and a hot drape former for 3D preform production, to be initially deployed to fulfill ASCEND project objectives.

-

Airborne, Accudyne partner to provide automated composites solutions worldwide

The two companies have signed an MOA to collaborate on further development of digital automation systems for composites manufacturing in aerospace, renewable energy, future mobility and more.

-

Plant tour: Qarbon Aerospace, Milledgeville, Ga. and Red Oak, Texas

Veteran aerostructures Tier 1 transforms into 21st century leader in thermoplastic composites and multiple new markets.

-

Fraunhofer IPT develops thermoplastic composites in hydrogen storage, engine blades and more

Active in laser-assisted tape winding and in-situ consolidation of thermoplastic composites since 1988, the IPT in Aachen, Germany continues to push new materials, applications and Composites 4.0 digital processing.

-

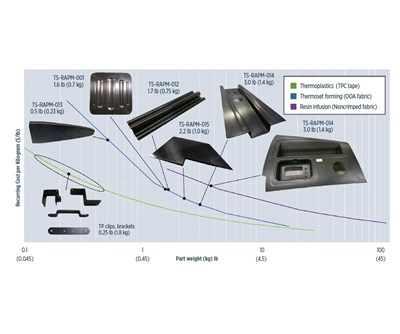

Revolutionizing the composites cost paradigm, Part 2: Forming

Boeing-led parts trials explore infusion, compression molding and thermoplastics, offering lessons and supply chain options to better compete with aluminum.

-

Automation options arise for labor-intensive composites

Typically labor-intensive fabrication processes have more automation options as new technology works in concert with operators to improve efficiency.

-

Consolidating thermoplastic composite aerostructures in place, Part 2

Thermoplastic composite structures could eliminate the autoclave and fasteners, but will a one- or two-step process prevail?

-

Consolidating thermoplastic composite aerostructures in place, Part 1

After more than 30 years of development, in-situ consolidation is nearing its promise to eliminate fasteners and the autoclave, and enable an integrated, multifunctional airframe.

-

20 years of automating composites

Accudyne Systems provides solutions to complex processing challenges, like its recent Small Parts Laminator that picks, places and forms plies in one minute.

-

Automating the CH-53K’s composite flexbeams

Accudyne doubles the part production rate and eliminates layup errors through stepwise automation of this primary structureÔÇÖs complex hand layup process.

-

Composites automation: Trending smaller and robotic

Although AFP and automated tape laying (ATL) lamination technologies are widely used in the aircraft industry, market conditions in the past few years are driving some changes in composites equipment supplier product lines. Consultant Carroll Grant explains why.

-

Status update on composites automation

Consultant Carroll Grant reviews progress made in recent years toward greater variety in automated composites processing machine sizes configurations and capabilities.

-

AFP/ATL design-to-manufacture: Bridging the gap

Managing production of a structure made via fiber or tape placement often requires software-aided manipulation of the subtle differences between that which is designed and that which can be manufactured.

-

Managing multi-axis manufacturing

Much early computer numerically controlled (CNC) machinery served short-run military and space programs where cost per part was too high to be acceptable in the manufacture of commercial aircraft. Now, Automated CNC machinery moves toward volume production and part-specific design.

-

Part-Purpose Manufacturing Simplifies Composite Part Production

The historically high cost of prepreg-based composite parts is often due to the painstaking hand layup that is required to create them. ÔÇťIt will be impossible to sustain composite part manufacturing levels that meet stringent quality standards if commercial OEMs rely only on manual labor,ÔÇŁ contends John Melilli, VP of