TFP innovations improve layup accuracy, speed and material versatility

JEC World 2025: ZSK Stickmaschinen is highlighting its latest innovations supporting tailored fiber placement, from integration of digital controls to multi-fiber placement capabilities.

Source | ZSK

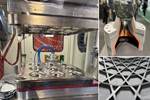

Industrial embroidery machines supplier ZSK Stickmaschinen (ZSK, Krefeld, Germany) is showcasing innovations to its tailored fiber placement (TFP) machines, including the integration of digital control systems, multi-fiber placement capabilities and smart material integration. These enhancements target more customized composite component production that is both precise and efficient.

Through these latest “additive manufacturing” TFP machines ZSK is addressing the growing demand for high-performance and tailored composite structures in the aerospace, automotive, sports equipment, consumable goods and medical markets.

ZSK TFP systems feature innovation in fiber placement accuracy, process automation, production speed and material versatility. For instance, they support multi- and interchangeable feeding systems, enabling the simultaneous layup of up to four continuous fibers, achieving production efficiency ramp-up and diverse material combinations. For advanced functionalization, ZSK’s technology now also offers the capability to lay three fibers and/or wires in parallel. This includes the integration of optical fibers for sensing applications and heated wires for thermal management, expanding the possibilities of smart composites.

A cross laser guidance system has also been integrated into the TFP machine’s head(s), enhancing placement accuracy and ensuring optimal alignment during fiber layup, boosting quality control and reducing manual intervention. An automated clamping system streamlines production with improved handling, minimized downtime and offers a secure hold on fibers during layup.

ZSK is also introducing a digital tensioning system for continuous fiber laying. This process ensures consistent fiber tension, improving mechanical performance in composite structures.

Visit ZSK at Booth G65 in Hall 5.

Related Content

-

VIDEO: Enhancing composite tooling with additive manufacturing

At JEC World 2025, CW editor-in-chief Scott Francis explored the latest advancements in composite tooling with Massivit and Sika.

-

ÂÌñÏ×ÆÞ presents JEC World 2025 show recap

Despite domestic and global uncertainties, this year’s international composites show delivered on numerous composites technological innovations and welcomed new players to the field.

-

JEC Composites Startup Booster 2025 finalists are revealed

Out of more than 100 submitted applications, the following 20 finalists have been chosen to pitch their composites innovation at JEC World 2025.