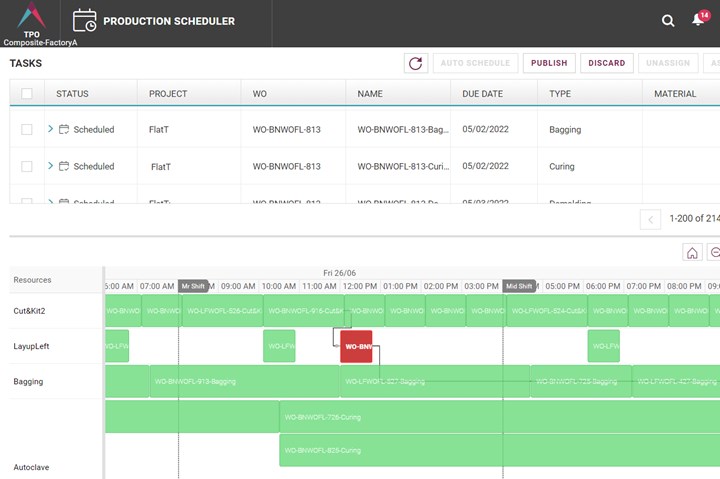

Plataine releases production scheduler version 4.0

The AI-based technology integrates production scheduling with shop floor management for a more efficient manufacturing process.

Source | Plataine

Plataine (Petach Tikva, Israel), provider of Industrial IoT (IIoT) and AI-based software for manufacturing optimization, has released version 4.0 of its cloud-based production scheduling application. Production Scheduler is part of Plataine’s Total Production Optimization (TPO) suite of applications such as Material & Asset Tracker, WIP Optimizer and Tool Manager, which integrates production scheduling with shop-floor management, streamlining production resources including materials, equipment and tools to make complex manufacturing processes more efficient.

Advantageous for planners and shop-floor employees, Plataine says its Production Scheduler provides a new, automated way to schedule and complete work orders, enhancing product operations according to set business KPIs (key performance indicators). Acting as a digital assistant, the application helps planners build a schedule and then monitors and adapts the actual production process, continuously improving it by comparing planned vs. actual development and reacting to unexpected events such as incoming rush orders, machine malfunctions and production delays. Applying AI-based technologies, the company says its scheduler also leverages bottleneck prediction and equipment efficiency.

Related Content

-

ST Engineering MRAS presents initiatives to drive autoclave efficiency, automation

During a JEC World 2024 panel discussion, the company revealed ways in which it is maximizing throughput and efficiency of its autoclaves and enhancing composites production processes.

-

Com&Sens presents workshop on fiber optic sensing for COPVs

Three-day hands-on workshop from June 11-13 in Leuven, Belgium, will equip participants with a better understanding of fiber optic sensing technology for digital manufacturing of composite tanks.

-

IMDEA introduces digital twin for real-time analysis of composite materials production

Newly designed digital twin by IMDEA and Technical University of Madrid researchers enables manufacturers to see inside composite materials as they are being produced, facilitating early detection of faults.