Spintech grows Miamisburg footprint to advance composite airframe capabilities

Additional 53,000 square footage, which could grow to 250,000 square feet of operational space by 2027, will support complex airframe component delivery for DOD, UAS programs.

Source | Spintech Holdings

(Dayton, Ohio, U.S.) recently announced a $7 million investment that is adding 53,000 square feet of dedicated high-volume manufacturing space to a plant in Miamisburg previously leased by Cornerston Research Group (CRG). The facility will be in addition to its current location at 1964 Byers Road in the same area, with majority of the investment going toward machinery and equipment that will be used to manufacture aerospace parts for critical defense and commercial systems.

Over the past 5 years, Spintech has evolved significantly, driven by customers’ demand for high-quality structural airframe components at lower costs and higher production rates. Historically, Spintech operated as a tooling provider through its Smart Tooling division, which offers solutions for aerospace composite (carbon fiber) manufacturing. Since its commercial launch in 2010, Smart Tooling has successfully been deployed on more than 50 flight-qualified aerospace systems, including high-profile platforms such as SpaceX’s Falcon 9, Boeing’s ecoDemonstrator, General Atomics’ SkyGuardian and Bell/Boeing’s V-22. However, as Smart Tooling products are reusable for up to 100 cycles, they generate limited sales volume, constraining revenue growth. To seek other growth opportunities Spintech started to explore other means to apply its composite processing knowledge.

The U.S. Department of Defense’s (DOD’s) pivot toward low-cost unmanned systems was what initially enabled Spintech to extend its work beyond tooling, resulting in the launch of Hawthorn Composites in 2021 to meet this demand. To this day, Hawthorn Composites delivers structural composite airframes and airframe components for unmanned aircraft, with capabilities that enable it to produce tens of complex airframe components — such as fuselages, wings, tails and nosecones — per day, positioning Spintech as a key supplier to DOD prime contractors and the DOD itself.

Over the last few years, Hawthorn has secured major contracts for six key unmanned aircraft system (UAS) platforms in both the defense and commercial space, progressing from engineering concepts through low-rate initial production (LRIP) and transitioning to high-rate production. The U.S. DOD’s current endeavors — ordering UAS for missions like intelligence, surveillance and reconnaissance (ISR), counter-unmanned aircraft systems (CUAS) and low-cost munitions — is further fueling Hawthorn’s growth.

Spintech’s newest leasing, bringing its total operational space to 90,000 square feet, will produce up to 533 airframes per month and host a Systems Integration Lab (SIL) in a controlled unclassified information (CUI) environment. The SIL will enable the Air Force Research Laboratory (AFRL) and third-party partners to integrate new payloads and flight controls onto Group II and Group III UAS (small- to medium-sized drones). The SIL will house vehicles that adhere to modular open systems architecture (MOSA) and weapons open systems architecture (WOSA) standards. This compliance supports rapid deployment of new capabilities, similar to an App store-like model, reducing time to field.

Looking ahead, Spintech anticipates adding a 60,000-square-foot facility and a 100,000-square-foot facility within 2 years to support other U.S. DOD program ramp-ups. If successful in transitioning engineered platforms to production, Spintech’s Dayton-area footprint could reach 250,000 square feet by the end of 2027.

What other growth projects is Spintech considering? Through its Hawthorn Composites division, Spintech is exploring strategic opportunities to drive growth over the next 12 months. Its team is pursuing additional composite airframe manufacturing contracts with defense and commercial UAS customers to expand its market presence. Spintech is also developing value-added services, such as enhanced manufacturing processes and integration solutions, to deliver greater value to existing customers.

Related Content

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreOtto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

Read MoreFirst Airbus A350 crash confirmed in Haneda

Shortly after touch-down, a JAL A350-900 aircraft recently collided with a De Havilland Canada Dash 8. Exact circumstances are still unknown.

Read MorePlant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

Read MoreRead Next

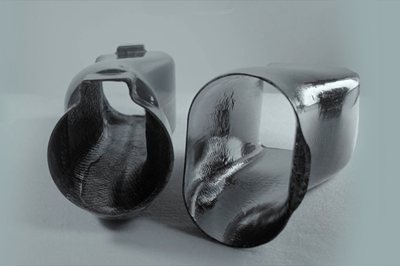

Braided carbon fiber & resin transfer molding for complex composites

Hawthorn Composites, a division of SpinTech Holdings Inc., reviews case studies of its high-value complex composites parts developed by deploying low-cost materials with resin transfer molding and novel manufacturing methods.

Read MoreSpintech awarded two U.S. STTR program contracts

Spintech partners with UDRI, an eVTOL OEM and Aurora Flight Sciences to explore manufacturing methods and materials for optimized eVTOL aircraft components and production.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More