Biesterfeld becomes exclusive distributor for Gen 2 Carbon

Recycled carbon fiber products will be introduced to new markets and industries via Biesterfield’s international network.

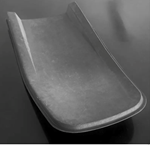

Gen 2 Carbon recycled carbon fiber (rCF) materials. Source | Biesterfeld

(Hamburg, Germany), an international distributors of specialty chemical products, pharma and food ingredients, is entering into a partnership with Gen 2 Carbon (Coseley, U.K.). With immediate effect, Biesterfeld will exclusively represent and promote Gen 2 Carbon’s recycled carbon fiber (rCF) products in European Union territories, Norway, Turkey and Switzerland.

Gen 2 Carbon’s materials transform waste materials into high-quality, reusable carbon fiber products. In addition to being environmentally friendly, they are reported to maintain high strength and lightweight properties associated with carbon fiber, making them ideal for a wide range of applications in automotive, aerospace, wind energy and marine industries.

“This collaboration aligns with our commitment to sustainability and innovation, providing our clients with materials that meet the growing demand for eco-friendly solutions,” notes Dr. Johannes Martin, market manager composites and tooling at Biesterfeld.

Through this partnership, Biesterfeld will leverage its extensive distribution network and market expertise to introduce Gen 2 Carbon’s products to new markets and industries. This collaboration will facilitate the integration of sustainable materials into manufacturing processes, supporting the transition towards a circular economy.

As the exclusive distributor, Biesterfeld will also offer comprehensive support to customers, including technical expertise, tailored solutions and logistics.

Related Content

-

Filament winding increases access to high-performance composite prostheses

Steptics industrializes production of CFRP prostheses, enabling hundreds of parts/day and 50% lower cost.

-

Carbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.