SAMPE 2010 Seattle at a Glance

A quick-reference timetable for the Society for the Advancement of Material and Process Engineering's SAMPE 2010 Conference and Exhibition, May 17-20, in Seattle, Wash.

The following schedule is based on information available from SAMPE on April 23, 2010. To view the rest of our SAMPE 2010 coverage, see "Editor's Picks," at right.

Monday, May 17

Registration 7:30 a.m. to 5:00 p.m.

Tutorials 9:00 a.m. to 12:00 p.m.

• Damage Tolerance and Assessment

• Nanotechnology – Overview

• Out of Autoclave Processing

• Dimensional Control and Process Modeling

Tutorials 2:00 p.m. to 5:00 p.m.

• Test Methods for Composites

• Composite Repair Technology

• Composite Manufacturing Technology

• Composite Tooling

Sessions 2:00 p.m. to 5:00 p.m.

• Nanocomposites I (ITAR)*

• Morphing Materials (ITAR)*

• Design for Impact

• Structural Health Monitoring

• Resins

• Sandwich Structures

SAMPE Fellow Banquet 6:00 p.m.

Tuesday, May 18

Registration 7:30 a.m. to 5:00 p.m.

Exhibit Hall Open 10:00 a.m. to 5:00 p.m.

Keynote Presentation 8:00 a.m. to 9:00 a.m.

Carbon Nanotube-incorporated Polymeric Nanocomposites:

Morinobu Endo (Shinshu University, Japan)

Featured Lecture 9:00 a.m. to 9:30 a.m.

Design and Manufacture of Composites on Military Aircraft:

Dr. John Russell (Air Force Research Lab)

Sessions 9:00 a.m. to 12:00 p.m.

• Testing

• NDE/NDI I

• Thermoplastic Composites I (ITAR)*

• M&P I (ITAR)*

• Out-of-Autoclave I

• Novel Materials and Applications

• Composite Process Modeling I

• Manufacturing I

• Adhesion & Adhesive Bonding I

• Student Symposium I

Panel 9:00 a.m. to 12:00 p.m.

• Commercialization of Nanotechnology

Featured Lecture 2:00 p.m. to 2:30 p.m.

Design/Analysis Trends in Aerospace

Composite Structures

Eric Cregger (The Boeing Co.)

Sessions 2:00 p.m. to 5:00 p.m.

• Nanocomposites II

• Design & Analysis I

• Thermoplastic Composites II

• M&P II

• Out-of-Autoclave II

• Novel Architectures, Hybrids, and

Coatings (ITAR)*

• Composite Process Modeling II

• Manufacturing II (ITAR)*

• Adhesion and Adhesive Bonding II

• Student Symposium II

Panel 2:00 p.m. to 5:00 p.m.

• Benchmarking of Composites

Welcome Reception 5:00 p.m. to 6:00 p.m.

Wednesday, May 19

Registration 7:30 a.m. to 5:00 p.m.

Exhibit Hall Open 10:00 a.m. to 5:00 p.m.

Keynote Presentation 8:00 a.m. to 9:00 a.m.

New Materials & Processes Driving Boeing’s Products

Frank Doerner (The Boeing Co.)

Featured Lecture 9:00 a.m. to 9:30 a.m.

Composites in Canada

Dr. Andrew Johnston (National Research Council Canada)

Sessions 9:00 a.m. to 12:00 p.m.

• Thermoplastic Composites III

• Adhesion & Adhesive Bonding III

• Nanocomposites III

• Design & Analysis II

• Rotorcraft I

• NDE/NDI II

• M&P III

• Liquid Molding Processes I

• Aircraft Applications I

Panel 9:00 a.m. to 12:00 p.m.

• Out of Autoclave Processing — Challenges and Opportunities

Featured Lecture 2:00 p.m. to 2:30 p.m.

Natural Materials

Mohini Sain (University of Toronto)

Sessions 2:00 p.m. to 5:00 p.m.

• Space Applications (ITAR)*

• Repair I

• Nanocomposites IV

• Design & Analysis III

• Rotorcraft II

• NDE/NDI III

• Natural Materials

• Liquid Molding Processes II

• Aircraft Applications II

Panel 2:00 p.m. to 5:00 p.m.

• Frontiers in Materials and Process Technology

Student Social Reception 5:00 p.m. to 6:00 p.m.

Thursday, May 20

Registration 7:30 a.m. to 2:00 p.m.

Exhibit Hall Open 9:00 a.m. to 12:00 p.m.

Featured Lecture 8:00 a.m. to 8:30 a.m.

Wind Energy

Dr. Enrique Garcia (Gamesa SA)

Featured Lecture 8:30 a.m. to 9:30 a.m.

Innovation: The Modern Energy Challenge

Dr. Ian Chatting (Vestas Wind Systems)

Sessions 9:00 a.m. to 12:00 p.m.

• Nanocomposites V

• Tooling

• Fracture and Failure

• Electromagnetic Effects (ITAR)*

• High Temperature / Liquid Molding (ITAR)*

• Recycling

• Wind Energy

• Nanocomposites VI

Panel 9:00 a.m. to 12:00 p.m.

• Advanced Composite Structural Repair Systems for the Future

Luncheon 12:30 p.m. to 2:00 p.m.

Sessions 2:00 p.m. to 5:00 p.m.

• Nanocomposites VII

• POSS Nanostructures

• Automated Fiber Placement

• Textiles

• Unmanned Systems

• Ceramics

• Repair II

• Nanocomposites VIII

Panel 2:00 p.m. to 5:00 p.m.

• Tooling for Composites: New Materials and Recent Trends

*Papers subject to ITAR (International Traffic in Arms Regulations) are export-restricted. Attendees must present appropriate ID and paperwork.

Related Content

Plant tour: Arris Composites, Berkeley, Calif., U.S.

The creator of Additive Molding is leveraging automation and thermoplastics to provide high-volume, high-quality, sustainable composites manufacturing services.

Read MoreCirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

Read MorePlant tour: Hexagon Purus, Kassel, Germany

Fully automated, Industry 4.0 line for hydrogen pressure vessels advances efficiency and versatility in small footprint for next-gen, sustainable composites production.

Read MoreRead Next

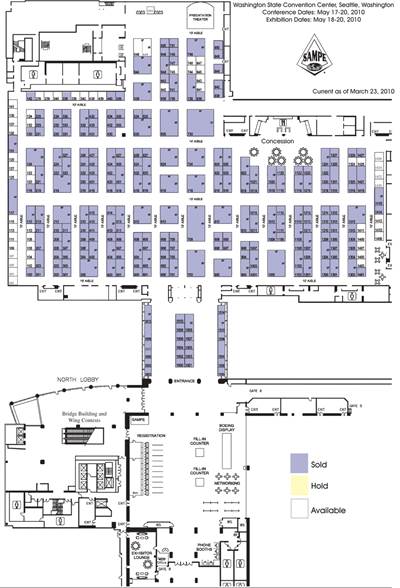

SAMPE 2010 Seattle Exhibitor List

A list of exhibitors, booth assignments and a show floor map for the SAMPE 2010 Seattle trade show, May 17-20, 2010.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More