Looking Forward

Current composite tether designs are leveraged to take advantage of existing oil-field manufacturing facilities. The wirerope stranding facilities, umbilical closing machines, steel anchors and installation methods used today for steel and synthetic cables can immediately accommodate rope-style composite tethe

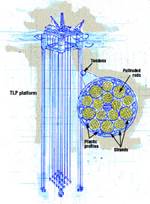

Current composite tether designs are leveraged to take advantage of existing oil-field manufacturing facilities. The wirerope stranding facilities, umbilical closing machines, steel anchors and installation methods used today for steel and synthetic cables can immediately accommodate rope-style composite tethers. However, future designs could be more flexible. Rods could be pultruded in any shape. Salama of Conoco adds, “We are looking at materials with a specific gravity lower than water to reduce the pretension.” For example, PVC profiles with a specific gravity of 1.4 could be replaced with polyethylene profiles that have a 0.9 specific gravity (10 percent lighter than water). Other lightweight options include polypropylene, polystyrene and acrylonitrile butadiene styrene (ABS). Alternatively, a tether could be manufactured from a single strand, which would greatly simplify the entire system. The Doris Engineering/Freyssinet partnership envisions an extension of composite cable technology to moorings for other floating deepwater structures, such as catenary cables for spars, semi-submersibles and production ships.

Related Content

-

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

-

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.