CAMX 2016 Exhibitor Previews: Part 2

CAMX, in its third year, is growing and expanding, and the quantity and quality of new products and technologies being introduced at the show is impressive. CAMX Connection asked exhibitors to tell us about the products they will feature, and the response has been tremendous. This week features Part 2 of 2 of the CAMX 2016 Exhibitor Previews.

, in its third year, is growing and expanding, and the quantity and quality of new products and technologies being introduced at the show is impressive. CAMX Connection asked exhibitors to tell us about the products they will feature, and the response has been tremendous. This week features Part 2 of the CAMX 2016 Exhibitor Previews.

The below list includes exhibitor name, a description of the technology or product being featured and a link to additional information. The exhibit hall at CAMX features more than 550 exhibitors offering a range of products, including resins, fiber reinforcements, machinery, tooling material, software, fabrication services, training services and more.

CAMX will be held Sept. 26-29, at the Anaheim Convention Center in Anaheim, California. Exhibit floor hours are 9:30 am-5:00 pm, Tuesday, Sept. 27 and Wednesday, Sept. 28. Exhibit floor hours are 9:30 am-1:00 pm on Thursday, Sept. 29.

For more information about CAMX, including conference schedule, exhibitor list and registration, visit .

- Adhesive Systems: Methacrylate adhesive systems.

- Adwest Technologies: Thermal oxidizers for VOC control.

- Akarmak: Autoclaves, up to 5m diameter, 50m long.

- Beijing Composite Materials: Pultruded composites.

- Beijing Jiapeng Machinery: Advanced composites fabrication services

- Bostik: Hot melt adhesives as well as web and film adhesives.

- CNAM Center/CAPE Lab, South Dakota School of Mines & Technology: Contract research and education center.

- Composite Alliance: Tooling solutions, custom machinery, process optimization services.

- Composites Europe: Germany-based composites trade show.

- Coosa Composites LLC: Structural and non-structural composite panels.

- CPIC Fiberglass: E-glass and other glass fiber products.

- Dantec Dynamics: Laser shearography systems for non-destructive testing.

- E.V. Roberts: Distributor of adhesives, sealants and surface treatments.

- ELG Carbon Fibre: Recycled carbon fiber reinforcements and nonwovens.

- Ellsworth Adhesives: Adhesives, specialty chemicals for aerospace applications.

- Engineering Technology: Small, lightweight desktop winder.

- FEI: Software for industrial inspection operations.

- Freeman Manufacturing & Supply: Modeling and tooling boards.

- Gabriel Performance Products: Epoxy additives.

- Globe Plastics: Aerospace composites manufacturing services.

- Hall Composites: Aerospace composites manufacturing services.

- HELD Technologie: High-performance, isobaric, double-belt presses.

- High-Performance Products: High-performance mold releases.

- HOS Technik: High-temperature resins, monomers, reactive diluents and microbeads.

- Laguna Tools: CNC machining centers.

- LEUCO Telecon: PCD diamond-tipped, diamond abrasive and CVD diamond-coated cutting tools.

- Lindau Chemicals: Anhydride curing agents.

- Lingrove: Natural fiber-reinforced composites.

- LMG: Hydraulic presses.

- Lucintel: Composites market analysis and consulting services.

- M.C. Gill Composites Center/University of Southern California: Fundamental and applied composites research.

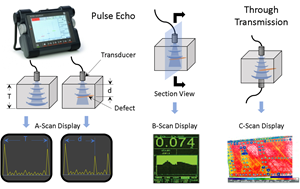

- Matec Instruments: Ultrasonic testing systems.

- Material Sciences Corp.: Specialty composites manufacturing services.

- MIKROSAM: Automated tape laying and fiber placement equipment.

- NDT Systems: Ultrasonic testing systems.

- Nederman: Environmental control systems.

- Netzsch Instruments North America: Thermal analysis equipment.

- Niabraze: Superabrasive electroplated and brazed products for cutting, milling and grinding.

- North Star Imaging: Computed tomography systems.

- Oak Ridge National Laboratory: 3D printing technologies, research and development services.

- Olmar: Autoclaves up to 10m diameter, 50m long.

- Omya: Ground and precipitated calcium carbonate.

- PakSense: Temperature monitoring solutions.

- Penso Group: Specialty tooling and fabrication services.

- Phoenix Inspection Systems: Ultrasonic, non-destructive testing scanners and transducers.

- Powerblanket: Resin curing blankets.

- Reinhold Industries: Composites and metals fabricator.

- REXCO: Mold release agents.

- RobbJack: PCD drill tools.

- Royce International: Cycloaliphatic epoxy resins and aliphatic curing agents.

- Rubbercraft: Extractable bladder tooling technology.

- Sanders Composites: Composites manufacturing services.

- Shikoku Chemicals: Imidazole curing agents for epoxy resins.

- Sicomin Epoxy Systems: Specialty epoxy matrix resins.

- SikaAkson US: Epoxy resin matrix systems.

- STELIA Aerospace North America: Aerospace composites manufacturing services.

- Stiles Machinery: 5-axis machining centers.

- Technology Design: Multi-probe and phased array ultrasonic systems for non-destructive evaluation.

- Tiger-Vac: Dust mitigation vacuum systems.

- Tiodize: Composite fasteners.

- T Plates Global: Sandwich structures design and manufacture.

- UCLA Department of Architecture and Urban Design: Composite architectural structures.

- Unicomposite Technology: Fiberglass pultrusion and pullwound services.

- Uni-ram: UV and infrared curing systems.

- Ventilation Solutions: Ventilation systems for composites manufacturing operations.

- Virtek/Gerber Technology: Laser projection and cutting table systems.

- YXLON: Metrology and inspection systems.

Related Content

CactuX in-situ BOX simulates real-life conditions of composite samples during CT analysis

The autonomous in-situ BOX combines the environment temperature control function and power supply function, enabling new possibilities for material and internal structure research.

Read MoreRuckus Composites, Aerospace grows in-house composites machining, measurement and inspection

Recent in-house technology investments set Ruckus up to meet advanced composite inspection and precision machining demand.

Read MoreNondestructive inspection methods available to composites manufacturers

An overview of composite laminate inspection techniques ranging from manual testing methods to more advanced, noncontact options.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreRead Next

Composites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More