Videos

In-mold coating offers high-performance finishing for epoxy-infused composites

ODG Composites’ Element Xtreme is a lightweight, long-lasting protective and aesthetic coating suitable for a range of industrial and commercial applications.

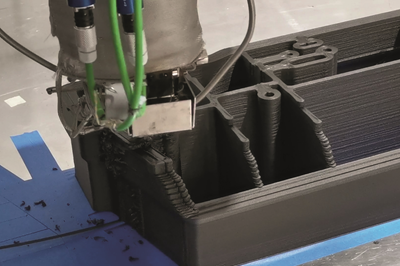

WatchCMS debuts hybrid LFAM/milling machine

The machining specialist has developed the first iteration of Kreator, a large-format, thermoplastic composite 3D printer and five-axis milling machine for tooling and jigs.

WatchElectroimpact launches plug-and-play AFP system

Automation and automated fiber and tape placement specialist Electroimpact has introduced Scorpion, a new modular plug-and-play automated fiber placement (AFP) system designed for research and laboratory applications.

WatchEpisode 39: Joe Fox, FX Consulting

Consultant Joe Fox talks about the massive potential for composites use in infrastructure applications and what it will take to turn that potential into reality.

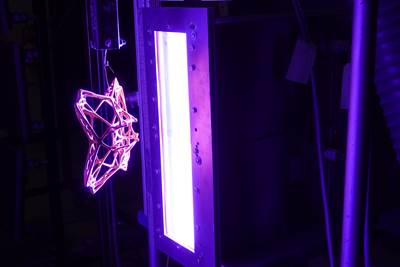

ListenApplying UV-curable powder coatings to composites

Keyland Polymer UV Powder reviews the features, benefits and applications of its UV-curable powder coatings in a composites manufacturing environment.

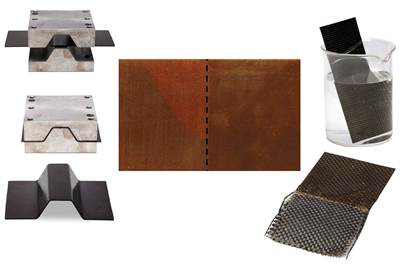

WatchReprocessable, repairable and recyclable epoxy resins for composites

CIDETEC matures 3R resins for aerospace applications via AIRPOXY program.

WatchWhy choose LSAM for large-format additive manufacturing?

Thermwood explores the features of LSAM, it’s large-format additive manufacturing system, including a product line summary, slicing software. (Sponsored)

WatchBraided preforms and resin infusion for next-generation aerocomposites

Spintech shows significant cost and labor savings using its Smart Tooling, dry fiber preforms and RTM/VARTM technology on aircraft wing and inlet duct demonstrators.

WatchNASA James Webb telescope completes primary mirror testing for 2021 launch

Tests ensured Webb’s primary mirror fully expanded and locked itself into place, as it would in space. Final tests will extend and restow radiator assemblies and deployable tower before launch date.

WatchAdvanced engineering thermoplastic adhesive hybrid resin

In this Digital Demo, L&L Products introduces T-Link, a new hybrid thermoplastic resin system, that does not require refrigeration or special handling and – being highly customizable – can be easily and quickly consolidated into a composite structure.

WatchEpisode 38: Alan Hiken, Kane Robotics

Alan Hiken, COO of Kane Robotics, talks about historic, current and future composites use in aircraft fuselage structures and the role of automation in next-gen manufacturing environments.

ListenNCC unveils AFP/ATL dual system for large, complex structures

The hybrid cell, created in partnership with Electroimpact, can be used individually or together for automated composite manufacturing at a medium- to large-scale level.

Watch