Workforce Development

Early bird deadline for Carbon Fiber 2016 fast approaching

Attendees who register on or before Oct. 10 get $100 off their conference fees – no code required.

Read MoreComposite repair: Lessons learned, challenges and opportunities, Part I

As aerospace companies look to increase the scope and quality of repairs, through standardized training and increased automation, their lessons learned (outlined here in Part 1 of a two-part examination) can smooth the repair path for other industries.

Read MoreAutomated Dynamics installs laser heating system at University

It will help provide the next generation of engineers exposure to the types of processes and technologies that will advance the composites industry.

Read MoreComposites enable portability in driving simulator

FRP design enables portable, light-tight, enclosure with an image-projection-grade inner surface.

Read MoreBMW 7 Series Plant: Dingolfing, Germany

Via four different manufacturing methods, CFRP goes mainstream in automated multi-material BIW and assembly operations at BMW’s busiest plant.

Read MoreMikrosam delivers automated filament winding line to Magna

Integrated production cell for high-volume production of composite CNG tanks installed in Graz, Austria plant.

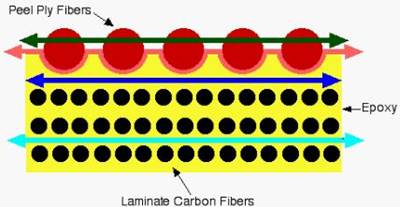

Read MoreWet and dry peel plies

Thinking of using only peel ply as adhesive bonding surface prep? You should understand all of the issues involved.

Read MoreCAMX 2016 Exhibitor Previews: Part 2

CAMX, in its third year, is growing and expanding, and the quantity and quality of new products and technologies being introduced at the show is impressive. CAMX Connection asked exhibitors to tell us about the products they will feature, and the response has been tremendous. This week features Part 2 of 2 of the CAMX 2016 Exhibitor Previews.

Read MoreThe power of personal connections

CW columnist and IACMI chief commercialization officer Dale Brosius suggests that composites industry “old-timers” need to figure out a better way to connect to the generations that are entering the composites workforce.

Read MoreCAMX 2016 Exhibitor Previews: Part 1

CAMX, in its third year, is growing and expanding, and the quantity and quality of new products and technologies being introduced at the show is impressive. This week features Part 1 of the CAMX 2016 Exhibitor Previews.

Read More