Thermoplastics

Preforming goes industrial: Part 2

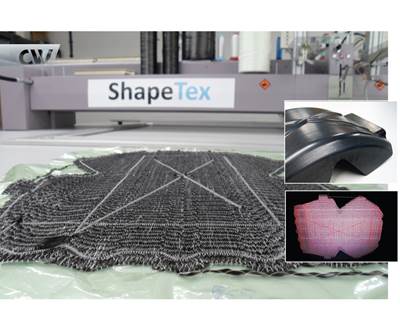

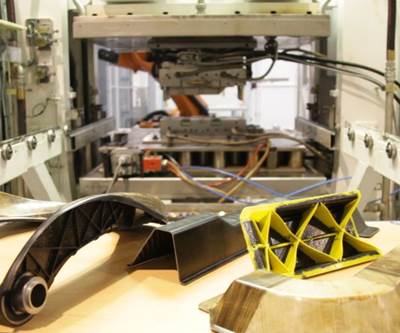

Automated preforming isn’t only for 2D and 2.5D parts. Innovators are taking successful aim at building 3D preforms at production speeds.

Read MoreCenter for mass production of lightweight composites

German R&D center brings together 8 institutes and more than 80 companies from 120 countries to help industrialize composite parts production.

WatchAutomated Preforming, Part 3: Quilted Stratum Process

CW’s tour of Cetim and the QSP line which preforms multi-thickness thermoplastic materials in 40-90 seconds for composite parts with cycle times of 1-2 minutes.

Watch2017 Paris Air Show is good for composites

There is definitely a lot going on this week at the Paris Air Show at Le Bourget airfield. Much of it relates to composites. Here’s a brief rundown.

WatchThermoplastic composite panels deliver affordable housing solutions

Modular construction concept takes composite housing another step forward, offering a wide range of comparably priced housing solutions to builders of all types.

Read MoreShape Machining shapes Elemental sports car

Designed and manufactured by a team of ex-McLaren designers, the recently launched RP1 features advanced aerodynamics and novel composite solutions, including an all-carbon composite passenger tub built to Formula 1 strength and stiffness standards.

Read MoreWhere are those promised composites technologies now?

Promising technologies of yesteryear: Where are they now? What can be learned from unfulfilled promise?

Read MoreAutomated Preforming, Part 2: Glide Forming

Flat layups are shaped into stringers with different cross-sections, lengths, thicknesses and curvatures using a single machine at rates up to 10 mm per second.

WatchPreforming goes industrial: Part 1

ATL and AFP-based preforming options now abound for processing dry and/or impregnated reinforcements as quickly as 1 minute or less with potential yearly part yields in the millions.

WatchComposites recycling: Gaining traction

Recycling of carbon fiber, glass fiber and — at last — resins, is growing as new players enter the space.

Read More