Sustainability

UMaine’s Offshore Wind lab sports 70m/230-ft testing … and more

The Offshore Wind Laboratory’s new wind turbine blade test lab, part of a 38,700-ft² (3,595m²) expansion of the University of Maine’s (UMaine) AEWC Advanced Structures and Composites Center (Orono, Maine), was first announced in February 2009.

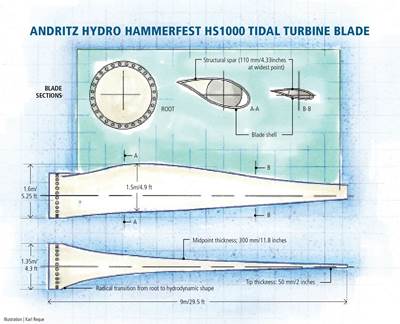

Read MoreTidal turbine blade toughened for turbulent salt sea

Demonstrator design proves robust blade destined for 10-MW tidal turbine farm.

Read MoreCured in place pipe: Trenchless trends

A variety of CIPP products are enabling the rehabilitation, rather than excavation and replacement, of underground pipe for wastewater and drinking water.

Read MoreCladding controversy: SMC insulation panels preserve pre-1919 building aesthetics

Acell (Milan, Italy) offers a solution for insulating older buildings that is designed to satisfy advocates of both architectural preservation and environmental conservation.

Read MoreStructural health monitoring: Angling for the air

Structural health monitoring (SHM) systems for composite aerostructures have been slow to deliver on their promise, but a system developed by Luna Technologies (Roanoke, Va.) is on a glide path to implementation on in-service aircraft

Read MoreIndustrial corrosion control: Huge opportunities

Fiber-reinforced plastic is the ideal but still widely ignored option in environments that eat away at most metal alloys. Opportunities abound, but the key is still education.

Read MorePrefabricated Bridge Elements and Systems: An opportunity for composites

The Federal Highway Admin. (FHWA) is keenly aware of the disruptions that highway and bridge projects impose on the traveling public. To address this need, the FHWA rolled out a series of accelerated bridge construction (ABC) initiatives. One involves prefabricated bridge elements and systems — a need the composites industry can easily meet.

Read MoreThe PTC: Symptom of policy uncertainty

The U.S. federal Production Tax Credit (PTC) is set to expire on Dec. 31, 2012, because Congress claims it cannot afford the yearly cost (estimated at $3.5 billion). Here's why Congress is wrong and who's really behind opposition to the PTC.

Read MoreAuto composites quest: One-minute cycle time?

Faced with high fuel prices and ever-more stringent restrictions on tailpipe emissions, automakers are taking composites into their own hands.

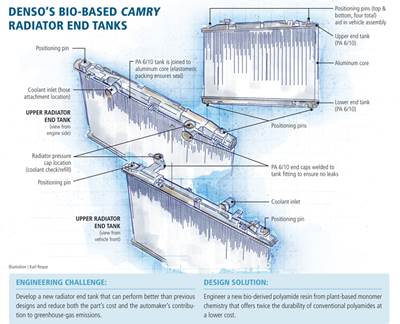

Read MoreCleaner and greener: Bio-based end tanks

Plant-based polyamides break high-cost/low-performance paradigm to meet the demands of a challenging Toyota underhood application.

Read More