RTM

Price, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

Read MorePlant tour: Dowty Propellers, Gloucester, U.K.

Transforming decades of design and RTM production reliability into more sustainable, next-generation composite propellers.

Read MoreHexcel joins collaboration program at Spirit’s Aerospace Innovation Centre

Collaborative activities include development of RTM production applications highlighting future opportunities for liquid composite molding.

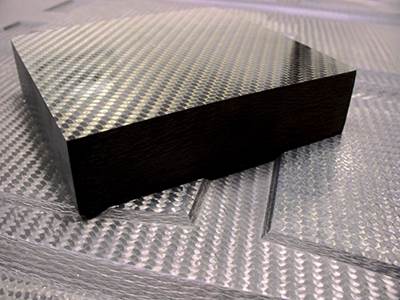

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreJEC World 2022, Part 1: Highlights in sustainable, digital, industrialized composites

JEC World 2022 offered numerous new developments in composites materials, processes and applications, according to CW senior editor, Ginger Gardiner, most targeting improved sustainability for wider applications.

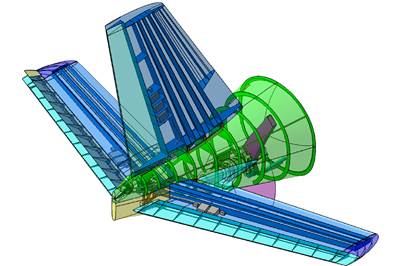

WatchMulti-flange RTM frames enable radical rear fuselage design

The Clean Sky 2 Advanced Rear End (ARE) demonstrator combines patented new frame design, thermoset and thermoplastic composites and smart tooling to advance aircraft design and cut weight, cost and production time.

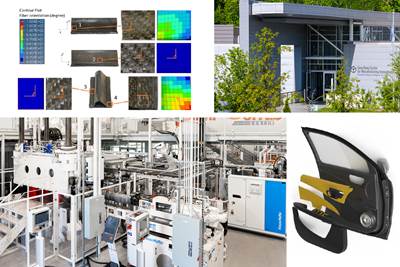

WatchClemson Composites Center: Working with industry to transform composites

Offering liquid and thermoplastic composites molding, LCA-weighted simulation, full testing to validate materials/process data cards, CCC’s digital life cycle approach unites manufacturing, microstructure, part property map and structural analysis.

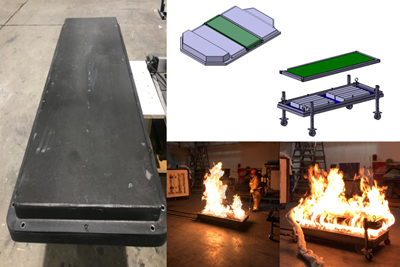

Read MoreMulti-material steel/composite leaf spring targets lightweight, high-volume applications

Rassini International was challenged by Ford Motor Co. to take weight out of the F-150 pickup truck. Rassini responded with a multi-material steel/composite hybrid leaf spring system that can be manufactured at high volumes.

Read MoreComposite rotary milking platform evolves via process innovations

Infusion and LRTM-based processes and design enabled Waikato Milking Systems to bring a lighter, less labor-intensive platform to the global dairy market.

Watch