RTM

Sensors: Data for next-gen composites manufacturing

In the quest for sustainability, sensors are reducing cycle times, energy use and waste, automating closed-loop process control and increasing knowledge to open new possibilities for intelligent manufacturing and structures.

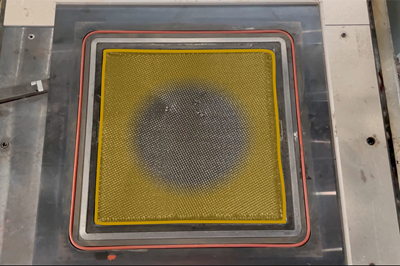

WatchNational Composites Center and Meggitt demonstrate linear dielectric sensor for liquid composites processing

Research at Cranfield University is further developed via RTM part trials in NCC’s Technology Pull-Through Program

Read MoreMiddle River Aerostructure Systems displays aeroengine nacelle using AFP and RTM composites

Highlights technologies and manufacturing processes that enhance aeroengine operating efficiency while reducing fuel consumption and noise.

Read MoreFingerprinting liquids for composites

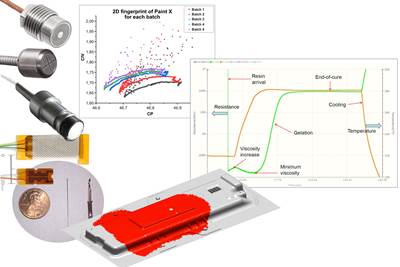

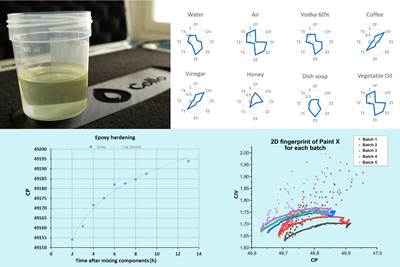

Collo uses electromagnetic sensors and edge analytics to optimize resin degassing, mixing, infusion, polymerization and cure as well as monitoring drift from benchmarked process parameters and enabling in-situ process control.

WatchCustomizing ultrasonic sensors for composites process optimization and control

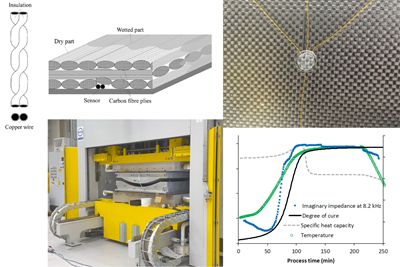

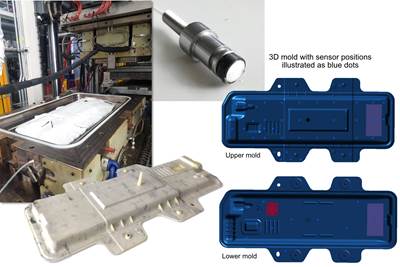

University of Augsburg developed sensors for the CosiMo project’s digital twin and closed-loop process control of EV battery box cover demonstrator, and now moves forward with the AI Production Network for industry collaboration.

Read MorePlant tour: Bucci Composites, Faenza, Italy

A stalwart in Italy’s “Motor Valley” opens its doors for a discussion and exploration of the company’s history in composites manufacturing for high-performance cars and other applications.

Read MoreSaab Aerostructures announces composite cargo door iteration, flaperon developments

Saab Aerostructures has reported updates to two of its composites-related projects, an RTM’d flaperon and the next iteration of the Clean Sky 2 technology demonstrator cargo doors.

Read MoreNexam Chemical, the NCC develop solution for manufacturing high-temperature composites

Nexam Chemical’s Neximid high-temperature resin system can operate at temperatures up to 400°C, expanding the boundaries of composites into more demanding applications that weren’t previously possible.

WatchDesigning for automated composites manufacturing of low-volume aerostructures

The commercial aerospace industry is heavily focused on design for efficient high-rate manufacturing, but there is still need for automated, affordable fabrication of low-rate aerostructures.

Read MoreAITIIP is developing innovative RTM tooling, ALM system for sustainable aircraft wing

HERON project methodology will be used to manufacture a composite aircraft wing demonstrator, which will be suitable to study the wing’s technical parameters and kinematic and aerodynamic properties.

Read More