Resins

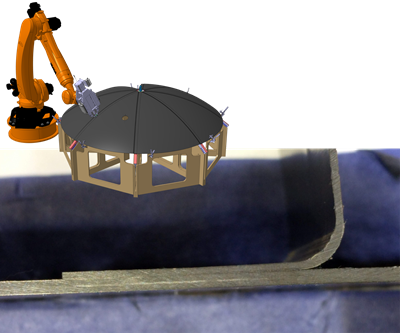

Continuous Fiber Manufacturing (CFM) with moi composites

Continuous fiber 3D printing using epoxy, vinylester and acrylic with continuous glass, carbon, basalt and other fibers, including deposition along nonlinear curves, is only the beginning.

WatchCAMX 2018 preview: Andara

Andara LLC (Sheboygan, WI, US) is featuring its line of styrene-free NOVOC resins for use in coatings, composites and other applications.

Read MoreCAMX 2018 preview: Olin

Epoxy manufacturer Olin Corp. (Clayton, MO, US) is unveiling several new technologies for composite applications, which will be shown in finished products on display in Olin’s booth

Read MoreCAMX 2018 preview: IDI Composites International

IDI Composites International (Noblesville, IN, US) is featuring its customized polyester/vinyl ester-based bulk molding compounds (BMC), sheet molding compounds (SMC), and an advanced line of Structural Thermoset Composites (STC - Ultra Performance Moldable Composites) that are manufactured in both sheet and bulk formats.

Read MoreCAMX 2018 preview: C. A. Litzler

C. A. Litzler Co. Inc. (Cleveland, OH, US) is debuting its improved standard thermoplastic prepreg machines, available for water-based and solvent-based resins in various widths and fibers, for use with multiple resins systems.

Read MoreNew PFA Composite has enhanced dry run capability

Greene Tweed’s new wear-resistant thermoplastic composite with a three-dimensional carbon-fiber architecture, offers enhanced performance over other PFA-based material.

Read MoreMusings about heat shields

NASA’s Orion capsule employs an ablative material based on the same heat shield coating used for the Apollo missions.

Read MoreA fascinating inside look at a marine design – three decades ago

Fabricated by Gougeon Manufacturing in 1990, Incognito is a composite catamaran that’s still setting speed records and besting much newer craft.

Read MoreRecyclable thermoplastic composites liftgates offer weight savings

Magna to launch two more thermoplastic liftgates this year.

WatchNew horizons in welding thermoplastic composites

Latest developments in qualification, production and applications for aerospace and automotive.

Read More