Processes

Composites Aboard High-Speed Trains

Greater demand for weight reduction and aerodynamics put railcar manufacturers on track to greater and more extensive use of composites.

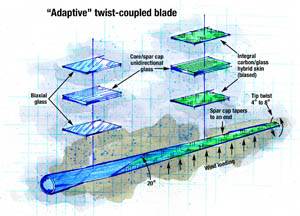

Read MoreAnisotropic wind blade design expected to reduce wind-energy costs

Deliberately unbalanced laminate produces smoother power input from adaptive wind blades

Read MoreAre high-temp thermosets ready to go commercial?

Developed for the U.S. military, these high-performance matrices are branching out into wider use.

Read MoreAbrasive machining methods for composites

Cutting, routing and drilling are important post-processing steps for cured composite parts.

Read MoreRacing Veteran Fine-tunes Classic Competitive Concept

Hand layup of reinforced epoxy yields hybrid luxury powerboat/offshore racer.

Read MoreThe Basics Of Boat Design

Naval architects reveal design, tooling and material selection guidelines for a new sportfishing powerboat.

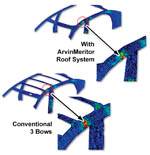

Read MoreRoof Module Reflects Well On Paintless Composites

Unique long-fiber injection process yields a paintless high-gloss finish, 20 percent weight reduction and improved safety -- all in one shot.

Read MoreTubular composite core stiffens launch vehicle structure

ChamberCore, an alternative to traditional sandwich laminates, also improves vibro-acoustic damping.

Read MoreTooling roundup: New materials, new methods

"Ingenuity" describes new tooling approaches for composites manufacturing.

Read MoreCarbon composites move beyond racing yachts into commercial and military marine applications.

Marine carbon composites move beyond racing yachts into commercial and military vessels.

Read More