Processes

Rocket engine thrust frame proves a strong candidate for composites conversion

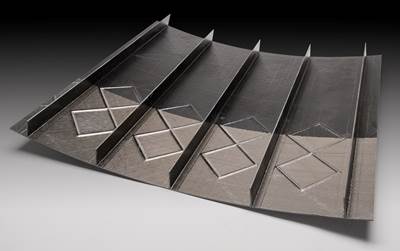

The engine thrust frame of a space launch vehicle, located at the bottom of a rocket stage, joining fuel tanks to engines, must deliver strength and stiffness across a range of temperatures — cost-effectively.

Read MoreSolvay launches adhesive and surfacing technologies for the aerospace industry

New AeroPaste and BR 179 adhesive and surfacing technologies are expected to increase part assembly, processing efficiency for aerospace manufacturers.

Read MoreComposites Integration expands Metyx partnership, appoints as U.S. distributor

Strengthened partnership expands RTM, infusion and technical textile offerings to U.S. markets.

Read MoreRegistration opens for Additive Manufacturing Conference + Expo 2021

Additive Manufacturing Media leading event for industrial 3D printing is expanding to include an expanded exhibit hall, speakers, exhibitors and networking opportunities.

Read MoreVictrex launches LMPAEK polymer grade for 3D printing

Victrex AM 200 improve melt extrusion by filament fusion (FF), direct granule extrusion, and laser sintering processes and enhances z-strength and interlaminar strength.

Read MoreCEAD launches new E50 Robot Extruder for larger 3D-printed composites

New option offers higher material output (e.g., 84 kg/hr) and thermoplastic melt temperatures up to 400°C.

Read MoreRoth Composites Machinery delivers customized filament winding system

Three-spindle system for the manufacture of hydrogen tanks boasts a flexible impregnation station and enhanced automation with a 40% increase in performance.

Read MoreFine Hulls brings bold boat design with Diab sandwich composites

The pleasure yacht is entirely made from Diab’s Divinycell foam sandwich core using a vacuum infusion process for excellent stiffness, strength and light weight.

Read MoreRobotic injection molding for functionalized composites

Anybrid enables compact, flexible hybrid injection molding/overmolding for smaller series and larger components.

WatchLEWCO presents enhanced-duty, vacuum-assisted composite curing oven

The composite oven, recently delivered to a U.S. military base, reaches a maximum temperature of 500°F and is used to cure vacuum-bagged composite aircraft parts.

Read More