Pressure Vessels

ULA selects Blue Origin's BE-4 Engine to power Vulcan

The liquefied natural gas (LNG) fueled booster will be powered by a pair of BE-4 engines, each producing 550,000 pounds of sea level thrust.

Read MoreCAMX 2018 preview: MultiMechanics

Composite modeling and simulation software specialist MultiMechanics (Omaha, NE, US) is demonstrating its newly released composite tube and pressure vessel optimization tool.

Read MoreIACMI announces collaborative smart composite pressure vessel project

The goal of the collaboration is to develop structurally predictable, low-cost smart composite pressure vessels (SCPVs) with integrated health-monitoring.

Read MorePlant Tour: Agility Fuel Solutions, Salisbury, NC, US

This systems integrator enables CFRP pressure vessel growth in commercial vehicles by combining composites and alternative fuel systems expertise.

Read MoreSteelhead Composites earns AS9100 certification

Steelhead Composites designs, manufactures and tests specialty, lightweight hydraulic components and composite pressure vessels to be used for weight-sensitive energy and fuel storage applications.

Read MoreRoth develops high-volume LPG tank line

The gantry-based filament winding system is designed to produce as many as 600,000 plastic-lined, glass fiber-overwrapped liquefied petroleum (LPG) gas pressure vessels per year.

Read MoreCAMX 2017 preview: Materia

Materia (Pasadena, CA, US), a supplier of high-performance catalysts and advanced polymers, is showcasing its Proxima high-performance resin product lines including ballistic-resistant test panels, large single-pour castings, high-temperature oil and gas downhole tools and sections of composite pressure vessels.

Read MoreNASA exploring using carbon nanotube for aerospace applications

NASA worked with Nanocomp to produce carbon nanotube (CNT) fibers to fabricate a carbon nanotube Composite Overwrap Pressure Vessel.

Read MoreNext-generation pressure vessels in space

After a name change, next on the horizon for Infinite Composites Technologies is supplying Type V tanks to the space race.

Read MoreNASA/Boeing composite launch vehicle fuel tank scores firsts

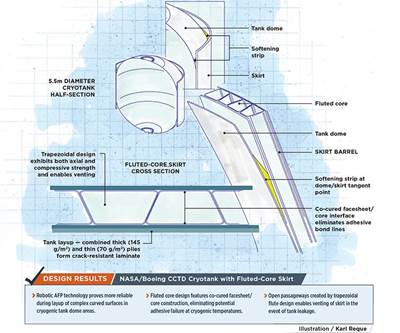

Subscale 5.5m-diameter cryogenic tank demonstrator with innovative fluted-core skirt is formed via robotic AFP and cured out of the autoclave.

Read More