PAEK

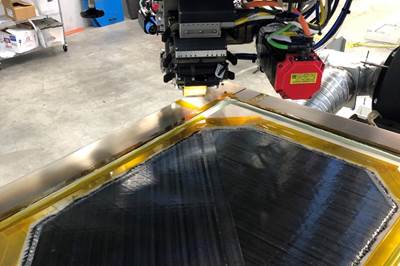

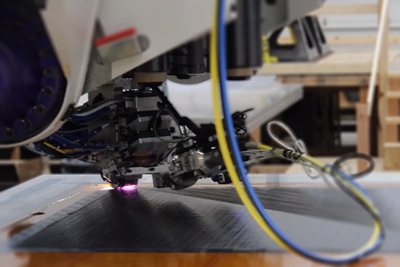

Electroimpact, Toray, Janicki advance technologies for rapid, large-scale thermoplastic parts manufacture

Project combines Electroimpact high-speed AFP equipment, Janicki’s OOA heated layup tooling system and Toray Cetex TC1225 low melt PAEK UD tape for deposition rates of up to 4,000 inches/minute.

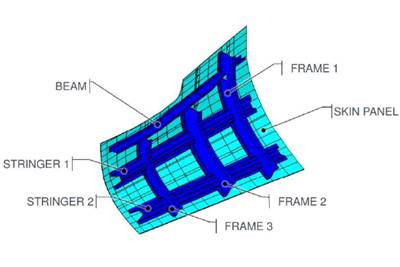

Read MoreClean Sky 2 FRAMES project advances heating simulation of thermoplastic composite AFP with xenon flashlamp

Heraeus Noblelight and Compositadour develop heating simulation to optimize process temperatures during automated fiber placement of composite aerostructures.

Read MoreOut-of-autoclave VBO rear spar, thermoplastic ribs target Wing of Tomorrow

French Tier 1 aerospace supplier Daher develops out-of-autoclave materials and process technologies for application in next-gen structures for the Airbus Wing of Tomorrow program.

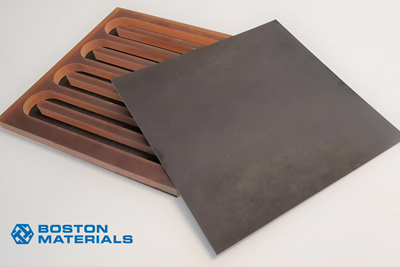

Read MoreCAMX 2021 exhibit preview: Boston Materials

Supercomp, ZRT and Bimetal are three of Boston Material’s z-axis carbon fiber products developed via its patented magnetic alignment process.

Read MoreCAMX 2021 exhibit preview: A&P Technology

A&P Technology’s new product offerings include slit tape thermoplastic fabrics that can be braided into fabrics up to 60 inches wide.

Read MoreVictrex launches LMPAEK polymer grade for 3D printing

Victrex AM 200 improve melt extrusion by filament fusion (FF), direct granule extrusion, and laser sintering processes and enhances z-strength and interlaminar strength.

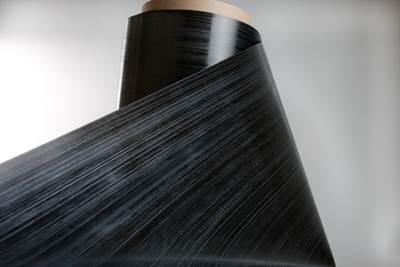

Read MoreTeijin Carbon Europe launches carbon fiber/PPS UD tape

The new Tenax prepregged tape with PPS matrix allows entry into new cost-sensitive markets while offering the typical TPUD advantages like resistance to chemicals and solvents, low flammability, storage or shipping at room temperature and recyclability.

Read MoreWing of Tomorrow ribs: One-shot, thermoplastic, OOA consolidation

GKN Aerospace’s carbon fiber thermoplastic aircraft rib design accomplishes 45-minute cycle times, reduced weight and competitive costs via a customized press system.

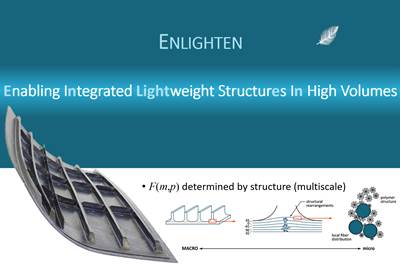

Read MoreENLIGHTEN program launched to speed thermoplastic composites industrialization

Multi-scale modeling, testing, sensors and machine learning will advance understanding and algorithms to achieve process control and optimization for both aerospace and automotive supply chains.

WatchVictrex, Electroimpact achieve thermoset AFP speeds using thermoplastics

Using Electroimpact’s AFP technology and Victrex’s low-melt PAEK prepreg tape, the companies report laydown speeds of 4,000 inches per minute.

Read More