Out of Autoclave

COMPOSITES & POLYCON 2009 preview

The ACMA’s annual tradeshow takes its first turn in its new January timeframe.

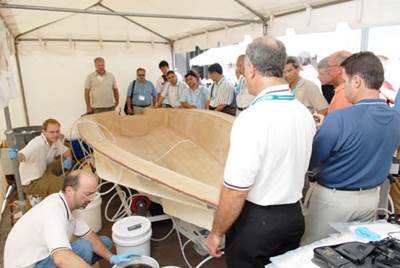

Read MoreIBEX 2008 postshow review

Despite a sluggish boatbuilding market, this annual Miami marine showcase was the platform for the introduction of innovative composite products.

Read MoreWatching a half-century of progress in composites

Looking back on my experience in the composites industry, from my first job in 1961 as a free-lance secretary to Brandt Goldsworthy to my last job as a free-lance writer for Composites Technology and High Performance Composites, gives me an uncommon perspective.

Read MoreUnmanned rotorcraft passes stringent German Navy shipboard tests

CAMCOPTER’s high strength-to-weight ratio is made possible by composite materials.

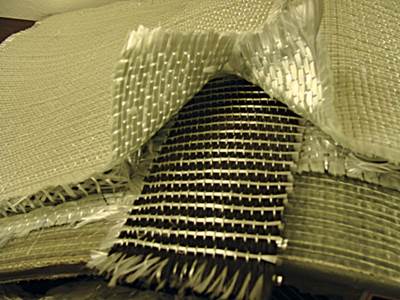

Read MoreWind Blade Manufacturing: Cost-efficient materials-based strategies

The wind blade’s four key elements — the root, the spar, the aerodynamic shell or fairing, and the surfacing system — have present unique manufacturing challenges that must be met with carefully selected composite material systems and molding strategies.

Read MoreWind Blade Manufacturing, Part I: M and P innovations optimize production

As demand for wind turbines reaches unprecedented levels, rotor blade manufacturers explore new production strategies, including automation and blade segmentation.

Read MoreWind Blade Manufacturing: Are thermoplastic composites the future?

In a market dominated by thermoset composites, some wind turbine blade manufacturers are actively pursuing new composite blade designs featuring faster-processing reinforced thermoplastics.

Read MoreHigh-Volume Preforming for Automotive Application

More than a dozen parts for four Aston Martin models are mass produced in France using Ford Motor Co.'s optimized Programmable Preforming Process and resin transfer molding.

Read MoreEngineered fiberglass cladding replaces metal for retail architectural applications

When FormaShape's (Kelowna, British Columbia, Canada) engineering manager Henry Czenczek approached Husky Energy, one of Canada's largest energy companies, his demonstration of the way fiberglass composites could dramatically improve the look, weatherability and vandal-resistance of the ribbed tin architectural cladding on Husky's Travel Centre retail outlets was enough to persuade Husky execs to overhaul the entire network. For the Husky project, FormaShape applied NEi Nastran finite element analysis software, Solidworks 3D, supplied by Noran Engineering Inc. (Westminster, Calif.

Read MoreComposites and Polymer Concrete Refine Mining Processes for Nonferrous Metal

Cost-effective alternatives to steel-reinforced concrete offer corrosion-resistant acid tanks to electrolytic refinery operations.

Read More