Out of Autoclave

SAMPE Europe/JEC Composites 2010 Preview

SAMPE Europe’s International Conference and the JEC Composites Show meet in Paris again in 2010.

Read MoreEngineering Insights: Not Your Father's EV

A stylish composite body makes the world's first all-electric sports car not only lean and green but efficient and fast as well.

Read MoreA400M cargo door: Out of the autoclave

This structural military airframe part is the largest made to date via the vacuum-assisted resin infusion process.

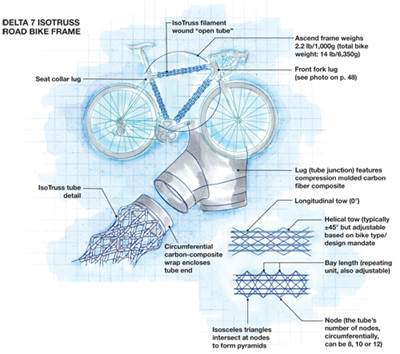

Read MoreNew twist in cycling: A truss bikers can trust

An "open tube" alternative to the solid-tube bike frame.

Read MoreDDG-1000 Zumwalt: Stealth warship

U.S. Navy navigates radar transparency, cost and weight challenges with composite superstructure design.

Read MoreNew infusion regime for superthick laminates

Innovative initiator chemistry yields long flow time, cure on demand and exotherm control for large, thick parts.

Read MoreUBSs: Coming to North America

Common in Europe and Asia, the composite underbody shield might finally catch on in the U.S. and Canada.

Read MoreGurit CBS for the Aston Martin DBS

Out-of-autoclave process mints Class A carbon composite body panels in one-hour mold cycle.

Read MoreAntiballistics: The DARPA connection

The Defense Advanced Research Projects Agency' (DARPA) Armor Challenge taps into materials innovation at companies and by inventors who are not yet in the military procurement pipeline.

Read MoreWichita welcomes SAMPE Tech

The Society’s Fall Conference flourishes in one of the epicenters of U.S. aerospace activity.

Read More