Out of Autoclave

Brazilian composites sector shows third consecutive year of growth

Maxiquim’s recent study notes that the transportation and electric sectors are responsible for $560 million in revenue.

Read MoreMHI Vestas wind blade materials to be sourced in Taiwan

Taiwan-based Swancor will supply resins and composite materials for MHI Vestas’ offshore wind projects in Taiwan.

Read MoreJEC Group announces 2020 Innovation Awards winners

The 13 winners were announced during a virtual ceremony on May 13.

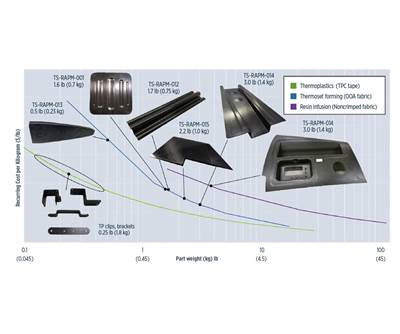

Read MoreRevolutionizing the composites cost paradigm, Part 2: Forming

Boeing-led parts trials explore infusion, compression molding and thermoplastics, offering lessons and supply chain options to better compete with aluminum.

Read MoreMaterial choices for the Corvette rear bumper beam

From fabrics to resins, a number of new combinations of materials went into the making of the world’s first curved pultruded automotive part.

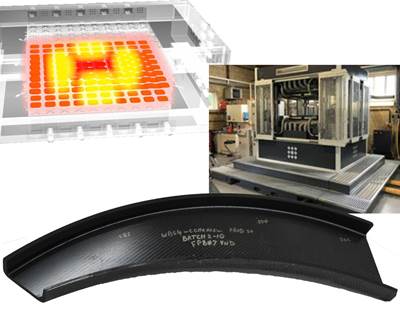

Read MoreRAPM development with PtFS

Boeing-led program explores rapid part cycles using automated, 180-channel thermal control molding cell for infusion, thermoset prepreg and thermoplastic composites.

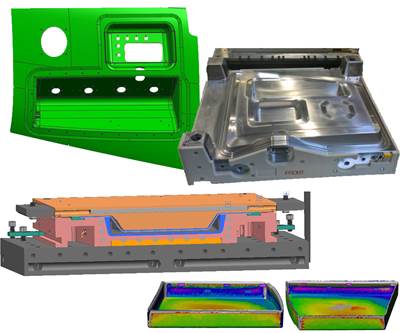

Read MoreManufacturing the complex geometry parts of RAPM

Boeing-led program explores simulation, tooling, preforming and molding approaches to lower composites part cost.

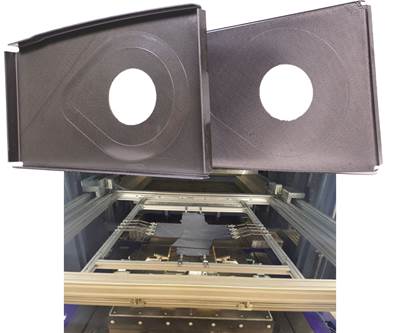

Read MoreNovel prepreg for compression molding in RAPM

Solvay and Boeing combine aerospace performance with process knowledge for high-rate, low-cost composites production.

WatchCurve in the road: First curved pultruded auto parts

Thomas Technik + Innovation KG’s radius pultrusion process unlocks new possibilities for the automotive market and beyond.

Read MorePark Aerospace Corp. introduces mid-toughened epoxy resin system

The E-752-MTS mid-toughened 350°F (177°C) cure epoxy system is designed for primary and secondary aircraft structure applications.

Read More