Materials

GE Aviation, Batesville, MS, US

With a supply chain busy making commercial jet engines like the GE90, GEnx, LEAP and GE9X, GE Aviation has invested heavily in its composites capabilities in Batesville.

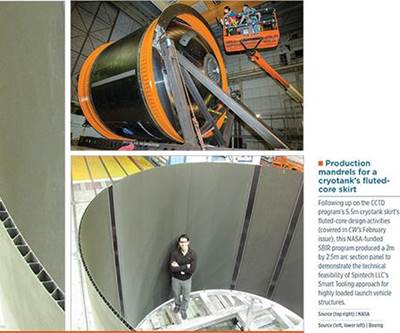

Read More“Smart tooling” cuts time and risk for complex unitized composite structures production

One-piece bladder tooling helps to actualize NASA/Boeing’s revolutionary fluted core design for next-gen cryogenic fuel tank skirt.

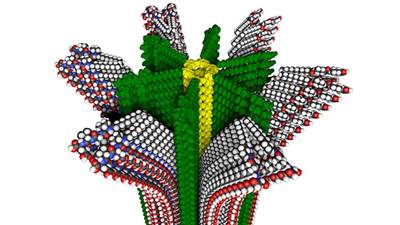

Read MoreNorthwestern University researchers develop a hybrid polymer

The university believes this could lead to new concepts in self-repairing materials, drug delivery and artificial muscles.

Read MoreFebruary supplement: Out-of-autoclave processing for aero use

We here at CW put together a supplement published with the February issue of the regular magazine that focuses on the technologies, tools and materials being used today in out-of-autoclave (OOA) processing for aerocomposites.

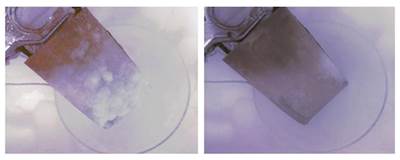

Read MoreGraphene composite could help keep wings ice-free

A thin coating of graphene nanoribbons in epoxy developed at Rice University has proven effective at melting ice on a helicopter blade.

Read MoreBoat propellers with replaceable, interchangeable blades

Long glass fiber-reinforced polyamide makes this modular propeller tough enough for a challenging application, eliminating costly prop repair.

Read MoreAlternative precursor R&D: What are the alternatives to PAN?

Carbon fibers made from other precursors are in use, commercially, and many more precursor alternatives have been investigated.

Read MoreAlternative precursor R&D: Oak Ridge National Laboratory

Oak Ridge National Laboratory (ORNL, Oak Ridge, TN, US) has been at the forefront of North American research into alternatives to the polyacrylonitrile (PAN) precursor used to make aerospace-grade carbon fiber.

Read MoreAlternative precursor R&D: Lignin in the lightweighting limelight

This abundant, renewable resource shows promise as an alternative to PAN for low-cost, functional carbon fibers.

Read MoreRecycled carbon fiber proves its potential for aircraft interiors

An Airbus-led team characterizes RCF veils and shows their ability to best glass fiber composite sidewalls in cost, weight and surface finish.

Read More