Materials

Plant tour: National Institute for Aviation Research, Wichita, Kan., U.S.

NIAR, located at Wichita State University in the heart of the American aerospace manufacturing industry, has evolved to become a premier hub of teaching, R&D, creativity and innovation.

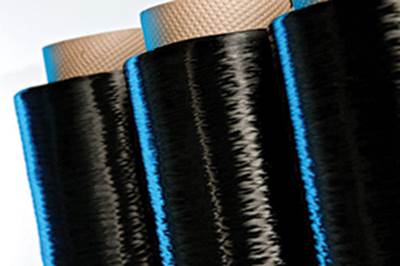

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreComposite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

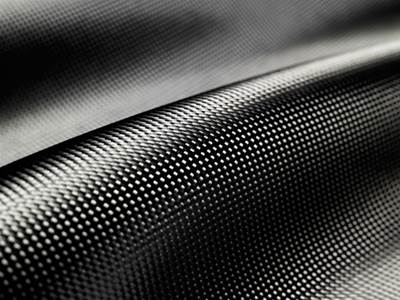

WatchMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreLoop Technology automates complex prepreg layup through FibreFORM system

Suitable for prepreg and dry fiber materials, FibreFORM is capable of picking, placing and laying up composite plies with high accuracy and precision, with three times the speed of manual layup.

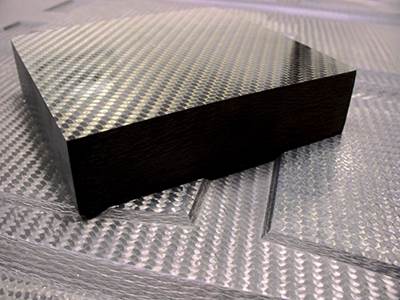

WatchVoith Composites partnership with Gazechim Group delivers Carbon4Tool tooling system to Europe

With Gazechim Group as the European distributor, Voith hopes to empower faster, easier and more effective CFRP tool manufacturing via its next-generation technology.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

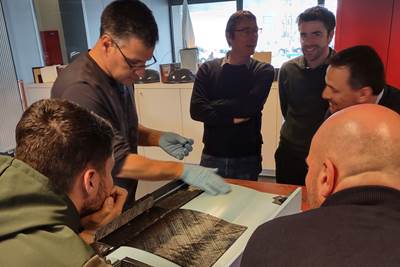

Read MoreFostering best practices for wet layup procedures

As fabricators continue to manufacture composite tools and parts using an open mold, wet layup process — often with mixed success — it’s important to stress proper preparation, materials, application methods and standardization.

Read MoreThe making of carbon fiber

A look at the process by which precursor becomes carbon fiber through a careful (and mostly proprietary) manipulation of temperature and tension.

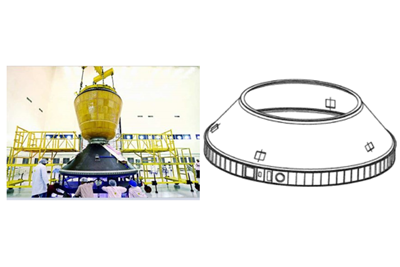

Read MoreKineco Kaman earns ISRO contract for India’s first human space flight mission

Three conical CFRP crew orbiter module adaptor (OMA) assemblies to be supplied for GSLV Mk-III by December 2023.

Read More