Marine

IBEX 2011 Preview

The world’s largest exhibition for the boatbuilding industry sets sail inland again, on the Ohio River. Destination: Louisville.

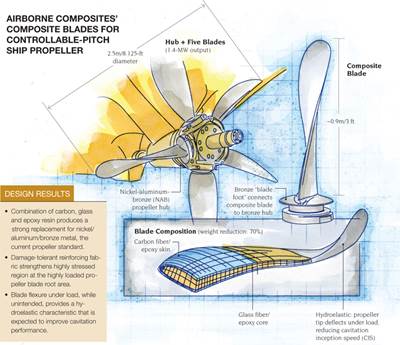

Read MoreComposite propeller for Royal Navy minehunter

Composite-for-metal replacement brings multiple benefits.

Read MoreRe-inventing the RHIB: Shock Mitigation

The U.S. Navy’s search for a lighter, load-absorbing rigid-hulled inflatable boat may end with this unconventional design.

Read MoreCabin cruiser: Making the most of a mirror finish

The hull mirror-like gel coat finish on the Daedulus 30 cabin cruiser was achieved through a combination of Marine Concepts’ (Lee-on-the-Solent, Hampshire, U.K.) mold design experience and fabrication techniques and materials provided by Scott Bader (Wollaston, Northamptonshire, U.K.).

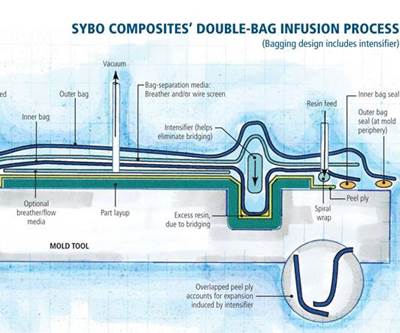

Read MoreDouble-bag infusion: 70% fiber volume?

A double vacuum-bag system and tight process control enable repeatable fiber volumes of 60 to 70 percent and improves consistency of infused laminates.

Read MoreIBEX 2010: Looking up in Louisville

A new location helps regenerate a recession-battered industry, drawing in more exhibitors and attendees than in 2009.

Read MoreMarine composites: A new dawn?

Boatbuilders fared worse than automakers during the recent recessionary storm. As the dark clouds dispel, there is some light on the horizon.

Read MoreIBEX 2010 Highlights

The world’s largest watercraft construction exhibition navigates new waters to its first inland rendezvous.

Read MoreDeepsea submersible incorporates composite pressure capsule

Spencer Composites Corp. (Sacramento, Calif.) fabricates the inner carbon/epoxy composite pressure capsule for a submersible deepsea vessel the late Steve Fossett was to take to the depths of the Pacific Ocean's Mariana Trench.

Read MoreThe state of education in the composites trade, part I

Andre Cocquyt (GRPguru, Brunswick, Maine) renews his call to focus composites industry efforts on finishing and financing a comprehensive unitary composites education model at the national level.

Read More