Aerospace

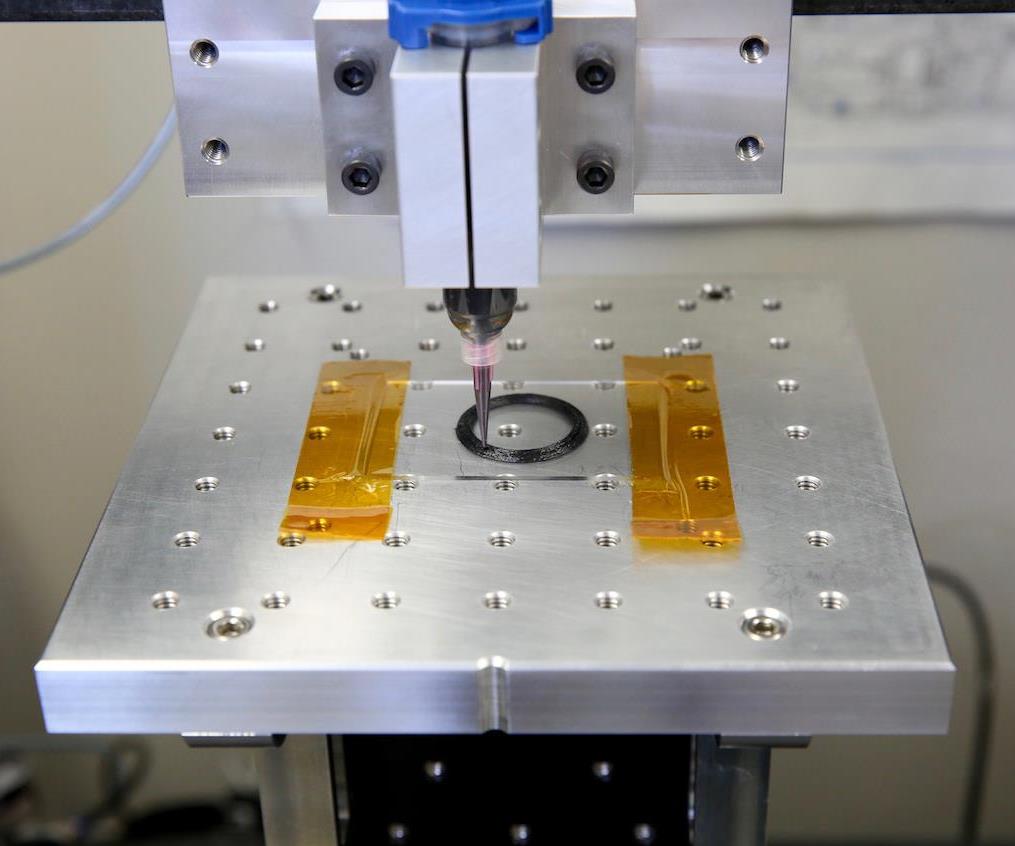

Researchers successfully 3D print carbon fiber

Lawrence Livermore National Laboratory (LLNL) researchers claim to be the first to 3D print aerospace-grade carbon fiber.

WatchGardner Business Index at 54.1 in January

The US composites industry looks as strong as it has since early 2015, with expectations the highest in years.

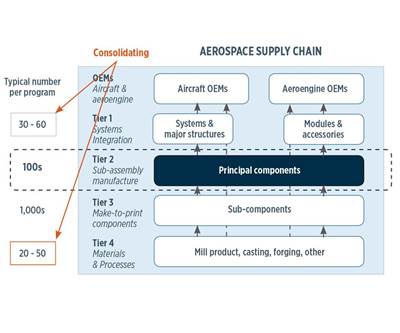

Read MoreAerospace composites in “the more for less” era

The past decade was about innovation and new technology. The next will be about productivity.

Read MoreNASA announces new commercial space market public-private partnerships

The agency is partnering with eight companies to accelerate the development of commercial capabilities to enable frequent launches of small spacecraft to low-Earth orbit.

Read MoreNASA carbon fiber glider to gather weather data during flight

The teams are still working on the design but the aircraft is expected to have a wingspan of about 3 feet and will be made of double ply, carbon fiber.

Read MoreGoogle shoots the moon

Google Lunar XPRIZE contenders turn to space- and launch-friendly composites.

Read MoreGE Aviation making progress on CMC facilities in Alabama

$200 million Huntsville operation to produce up to 20 metric tons of material a year.

Read MoreMachine vision: Rapid error detection

Aerospace-aimed ply placement technology evolves into process management and near-real time inspection system for production laminated composite parts.

Read MoreCompression molding: New materials and markets

From multifunctional aircraft interiors to compounds using continuous fabrics to the growing use of recycled carbon fiber – compression molding offers new opportunities.

Read MoreLockheed Martin, Pentagon reach deal for “lowest-priced” F-35s in program history

The contract is for 90 stealth fighter aircraft and represents more than a 60% price reduction for the F-35A variant since the first LRIP-1 contract.

Read More