Adhesives

Under the hood: Thermoplastics tackle tough jobs

Reinforced plastics save weight and cost, increase underhood productivity.

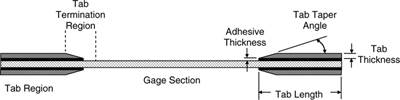

Read MoreTabbing composite test specimens: When and why

Dr. Don Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) discusses when and why test specimens must be protected by tabs.

Read MoreLow-volume thermoplastics: Differential pressure molding

Cost-effective tooling and presses enable semi-automated prototyping and low-volume production of thermoplastic composites.

Read MoreDesigning bicycling’s lightest pro racing frame

Cervélo’s Vroomen White Design group combines analysis and manufacturing acumen to create a 675g/1.5 lb composite frame.

Read MoreCabin cruiser: Making the most of a mirror finish

The hull mirror-like gel coat finish on the Daedulus 30 cabin cruiser was achieved through a combination of Marine Concepts’ (Lee-on-the-Solent, Hampshire, U.K.) mold design experience and fabrication techniques and materials provided by Scott Bader (Wollaston, Northamptonshire, U.K.).

Read MoreOut-of-autoclave prepregs: Hype or revolution?

Oven-cured, vacuum-bagged prepregs show promise in production primary structures.

Read MoreOld is new in vacuum bonding honeycomb sandwich

In Care and Repair of Advanced Composites (published by the Warrendale, Pa.-based Society of Automotive Engineers in 1997), Dr.

Read MoreLife Cycle Assessment: Are composites "green"?

Methods for calculating the impact composites have on the environment enable data-driven comparisons to traditional materials on a level playing field.

Read MoreIBEX 2010: Looking up in Louisville

A new location helps regenerate a recession-battered industry, drawing in more exhibitors and attendees than in 2009.

Read More