Adhesives

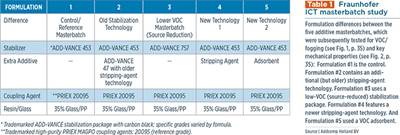

VOC reduction strategies for LFRT composites

Additives supplier seeks novel methods to limit VOC emissions from long-fiber-reinforced thermoplastics.

Read MoreMubea Carbo Tech: High-quality auto composites go high-volume

Known for its precision and technical acumen in CFRP motorsports structures, MCT draws from its steel auto parts parent to push high-performance and industrial production to new plateaus.

Read MoreComposites upgrade marine infrastructure

All-composite docks best concrete in cost and time and aim toward future fastener-less construction for greater savings and sustainability.

Read MoreAutomotive composites: Thermosets for the fast zone

Epoxies continue to be developed for faster cure to meet automotive production rates.

Read MoreLooking to lighten up aircraft interiors? Try natural fibers!

Aircraft OEMs are striving to make their products more efficient, with improved engines and ever-increasing use of composite materials, including in aircraft interiors.

Read MoreDesigning SHM systems

SHM systems must be designed properly, including self-diagnostic ability to ensure they function as designed.

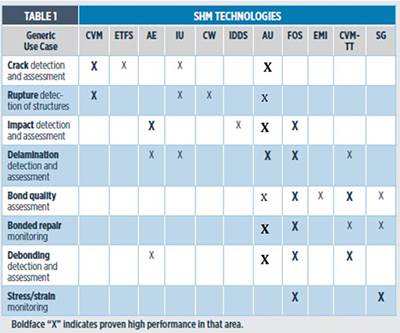

Read MoreStructural health monitoring: The toolbox

There are a broad range of SHM technologies that take advantage of a variety of sensing mechanisms. Here's a short sketch of each, accompanied by tables that indicate current uses and developmental progress.

Read MoreStructural health monitoring: NDT-integrated aerostructures

SHM moves from structural testing to an FAA-qualified inspection alternative, to reduce cost, streamline operations and mature toward lighter, more robust smart structures

Read MoreResins for the Fast Zone

An automotive supplier must have the ability to produce a composite part in a minute, or at least in minutes — not hours or days, the norm for composites in most other industries. Meeting that part-per-minutes goal is a huge hurdle that a few composite fabricators have cleared, and many more are involved in development efforts, with OEM or Tier partners. ÂÌñÏ×ÆÞ reviews how resin suppliers have evolved their products for this critical market.

Read More