Adhesives

The emerging commercial space industry

A decade since NASA opened extraterrestrial space to potential use as a commercial industry workplace, CW traces the role composites have played in public/private progress toward that goal.

Read MoreNanocomp Technologies Inc., Merrimack, NH, US

Its millimeter-length macro CNTs are finally realizing their commercial composites potential, with spacecraft applications leading the way.

Read MoreGetting real: Thermoplastic resin transfer molding

KraussMaffei is launching this fall thermoplastic resin transfer molding (T-RTM), through which caprolactam is injected into a preform and then in-mold polymerized to create polyamide 6.

Read MoreArgosy International expands on Taiwan expansion

Argosy’s composites manufacturing services manager, Thibaud Brunel, recently agreed to answer some questions about Argosy’s activities in the APAC aerospace sector.

Read MoreFine-tuning fiberglass: Smart fiber sizing

Some insights into those proprietary chemistries that can customize performance at the fiber/resin interface.

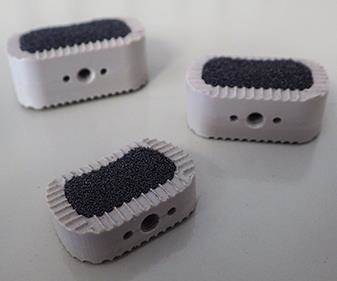

Read MoreOrthopedics: Carbon foam fosters bone growth

The Center of Innovation for Biomaterials in Orthopedic Research (CIBOR) at the National Institute for Aviation Research (Wichita, KS, US) has two patents on the use of carbon foam as a bone-graft material to improve success in orthopedic implants.

Read MoreTaking the hit without added weight

High-modulus polypropylene (HMPP) fiber hybrids graduate from tennis to ... tornados!

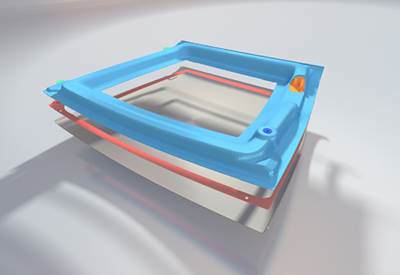

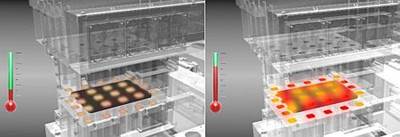

Read MorePixelated temperature control

Surface Generation is providing digital process control for composites molding that cuts energy use, cycle time and processing pressures while breaking boundaries in thickness, complexity and embedded elements.

Read MoreVABO Composites: Dutch innovator excels in diverse applications

From yacht masts and ship doors to front loader buckets and architectural projects, VABO uses resin infusion and ingenuity to push composites forward vs. metals.

WatchCarbon/epoxy Cadillac hood

Automated process for prepreg hood inner/outer cuts weight by 20% and yields Class A exterior out of the autoclave.

Read More