Adhesives

Composite design selected for salmon tracking antenna

Tough and affordable ultrathick laminate the solution for fish counting application.

Read MoreMold release update

New products from mold release manufacturers emphasize ease of use and application flexibility.

Read MoreComposite big-rig sleeper boxes offer comforts of home

Truckers are getting better sleep in their "homes away from home," thanks to composite sleeper boxes and cab floors manufactured by Canadian Commercial Vehicles (CCV, Kelowna, BC, Canada). Incorporated on Western Star (Willoughby, Ohio) semi-trailer trucks to decrease noise and weight and increase payload and

Read MoreSITE Manufacturing

SITE Manufacturing (Redding, Calif.) has taken knowledge acquired during more than 23 years of producing hi-tech carbon composite components, such as telescope housings (for Celestron, see story on p. 20), and applied it to the sport of paintball. "One year around Christmas, we decided we wanted to do something else,"

Read MoreComposites on the frontlines

Armored vehicle applications on the ground and in the air fuel a growing, evolving market forhigh-performance materials.

Read MoreCarbon fiber raises consumer performance index

Carbon bridges gap between large-volume sporting goods and aerospace to satisfy discriminating tastes in consumer and professional markets.

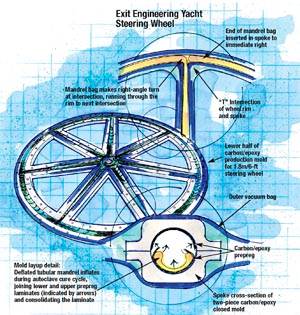

Read MoreOne-piece molded carbon steering wheel for yachts

Concurrent product and manufacturing system design creates lightweight, hollow spoked structure without joints.

Read MoreComposites Cut Costs Of Repairing Corrosion-Prone Systems

Composites materials and processing methods extend the useful life of noncomposite structures in industrial and infrastructure systems.

Read MoreAnisotropic wind blade design expected to reduce wind-energy costs

Deliberately unbalanced laminate produces smoother power input from adaptive wind blades

Read MoreAbrasive machining methods for composites

Cutting, routing and drilling are important post-processing steps for cured composite parts.

Read More