Additive Manufacturing

Moving continuous-fiber 3D printing into production

With patents proliferating and production applications emerging, 3D printing with continuous fiber reinforcement is poised for significant market growth.

Read MoreJEC World 2019 preview: CGTech

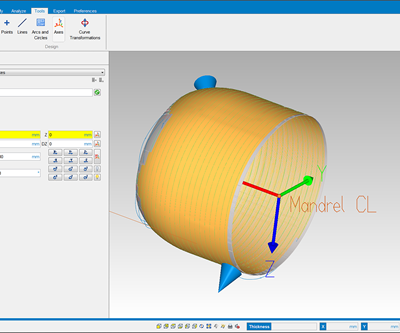

CGTech (Irvine, Calif., U.S.) is demonstrating how advanced programming strategies and simulation can lead to better composite parts at JEC World 2019, Stand Q49, Hall 5.

Read MoreStratasys software streamlines design-to-3D printing process

The company’s Advanced FDM software reportedly eliminates CAD-to-STL conversion, speeding part processing.

Read MoreEpisode 23: Wiener Mondesir, Arevo

Wiener Mondesir, co-founder and chief technology officer at Arevo, discusses continuous fiber use in additive manufacturing.

ListenThermwood and Bell collaborate on 3D-printed helicopter blade mold

Thermwood employed its new 60-mm melt core technology to additively manufacture the autoclave-capable, carbon fiber-reinforced tool.

Read MoreComposites recycling — no more excuses

Columnist Dale Brosius outlines six actionable levels of composites recycling that fabricators should follow.

Read MoreCarbon fiber will enable air taxi eVTOLs

Aircraft and autos have indeed faced CFRP production woes, but new tech opens door for both.

Read More3D printing is missing the third dimension

Emerging processes like continuous fiber manufacturing, in-situ consolidation and tool-less manufacturing are bringing composite 3D printing into the third dimension.

Read MoreNew Products: January 2019

CW’s roundup of new products for the composites industry – the past month has seen innovations from AnalySwift, BriskHeat, Granta Design, JETCAM, Kordsa, Starrett and Thermwood.

Read MoreTAHOE Boats' T16 uses 3D printed tooling from Thermwood

Thermwood’s Large Scale Additive Manufacturing (LSAM) system was utilized to custom-print the tool used to manufacture the boat’s hull.

Read More