Additive Manufacturing

Impossible Objects printer speeds composite 3D printing

The CBAM-2 3D printing machine combines is said to rapidly produce stronger, lighter high-performance 3D composite parts.

WatchArris Composites raises funding for high-speed composites manufacturing

The new proprietary process is said to produce low-cost carbon fiber composites for aerospace, automotive and other industries.

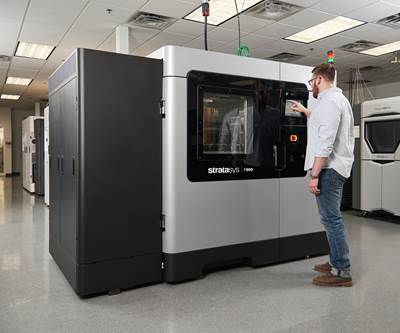

Read MoreSolvay, Stratasys partner for additive manufacturing

The companies will develop an aerospace-grade polymer for use with Stratasys 3D printers.

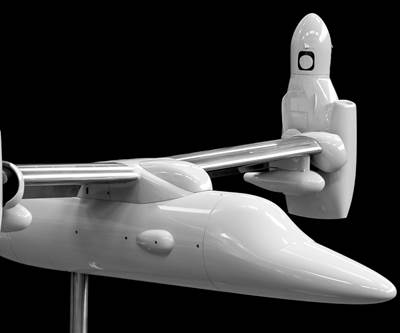

Read MoreAdditive manufacturing speeds wind tunnel model creation

A new composite material was developed to 3D-print a helicopter model that met structural needs while providing flexibility for fast reproduction.

Read MorePlataine chosen for Swinburne-led project to advance Industry 4.0 manufacturing of industrial scale composites

At the SAMPE 2019 conference, the Australian Government’s Global Innovation Linkages Program announced funding for a joint project with Plataine, led by Swinburne University of Technology, to research techniques for manufacturing high volume, lightweight composites.

Read MoreUAMMI, Impossible Objects build composite parts for U.S. Air Force

UAMMI is using Impossible Objects’ composite 3D printing technology to build 3D-printed carbon fiber/thermoplastic replacement parts for defense aircraft.

Read MoreTooling technologies positioned for speed, control

Tooling is one of the most rapidly evolving segments of the composites industry, as new technologies and processes like 3D printing, OOA infusion, thermoplastic composites reshape how molds are made.

Read MoreImpossible Objects partners with BASF for composite 3D printing

The companies announce a partnership for carbon fiber/PA6 composite 3D printing.

WatchDSM and CEAD partner for FGF 3D printing

The companies plan to develop new materials and processes for continuous fiber 3D printing and diverse end market applications.

Read MoreCarbon fiber-reinforced parts 3D-printed for catamaran

A Swiss engineering company combined 3D printing, bonding technology and carbon fiber composites to develop lighter, more efficient marine bearing cages.

Read More