Radius Engineering Inc.

1042 West 2780 South

Salt Lake City, UT 84119 US

801-886-2624

sales@radiuseng.com

About Radius Engineering Inc.

IS THIS YOUR COMPANY?

As Seen On ÂÌñÏ×ÆÞ

Editorial, News, and Products

-

Automated RTM, SQRTM enhance aerospace composites serial production transition

CAMX 2025: Coexpair, in partnership with Radius Engineering, combines equipment development and fabrication with engineering of composite parts, demonstrated in its European customer support, deliveries.

-

Software platform improves composites manufacturing automation

CAMX 2025: Radius Engineering introduces Insights, integrated software that automates critical functions in RTM and SQRTM processes, boosting efficiency and reducing human error and training needs.

-

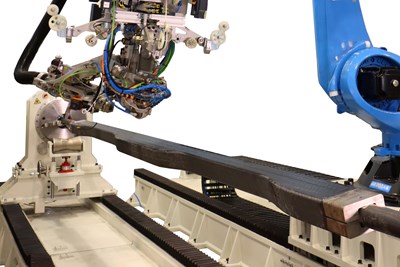

Radius Engineering supplies NIAR with thermoplastic consolidation workcell

NIAR ATLAS facility will use the workcell to produce precisely consolidated laminates for thermoplastic aerospace structure process strategy development.

-

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

-

Radius Engineering workcell enables composite flare housings for F-35

New flare housing manufacturing facility will utilize RTM workcell from Radius Engineering to manufacture composite housings for the F-35 Lightning II aircraft’s countermeasure flares.

-

Developing next-generation composites talent

The M.C. Gill Composites Center at the University of Southern California has steadily grown to become one of the industry’s educational and R&D stalwarts.

-

JEC World 2016, the full report

ÂÌñÏ×ÆÞ's editors report on the technologies and products that caught our eye at JEC World 2016, in early March.

-

GE Aviation, Batesville, MS, US

With a supply chain busy making commercial jet engines like the GE90, GEnx, LEAP and GE9X, GE Aviation has invested heavily in its composites capabilities in Batesville.

-

Reducing manufacturing cost via RTM

Airbus Bremen aims to replace dozens of prepreg components and assembly operations with a unitized multispar composite flap molded in a one-shot process.

-

The rise of HP-RTM

Decades of development have propelled it to prominence but its future demands industrial solutions for handling cost, complexity and process control.

-

JEC Europe 2014 Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

The market for OOA aerocomposites, 2013-2022

In the coming decade, out-of-autoclave technologies will increase composites penetration into primary flight structures.

-

HPC's 20th Anniversary: Thanks to HPC’s charter advertisers

Every trade publication lives and dies by its advertisers, and those who had the gumption to ante up for HPC’s premier issue are listed here and those who are still with us (see page numbers below) are gratefully recognized with the HPC 20th Anniversary Medallion.

-

SAMPE Europe 2013/JEC Europe 2013 highlights

Held concurrently, these two seminal European composites events weathered a rare Parisian snowstorm to plumb the depth and breadth of the industry.

-

Tooling for composites: Evolutionary trajectory

New technologies and improved methods keep up as tools get bigger and more complex and toolmaking gets ever more challenging.

-

SQRTM enables net-shape parts

New out-of-autoclave process combines resin transfer molding with prepregs for complex helicopter part prototype.

-

Automate or emigrate

Automated fiber and tape placement is not just a notion, but a real manufacturing strategy, and one being embraced by HITCO Carbon Composites.

-

Autoclave Quality Outside The Autoclave?

Pioneers of out-of-autoclave processing in aerospace applications answer a qualified but enthusiastic Yes!

-

SAMPE Wrap Up And Product Showcase

Exhibitions on both sides of the Atlantic spur optimism and spotlight innovative technology.

-

New Approaches To Cost-effective Tooling

New methods, materials and philosophies add up to tooling innovations.