Search Results

Showing 391 – 400 of 777 results

Processes in composites manufacturing encompass a diverse array of techniques employed to fabricate composite materials. These processes include methods like hand layup, where layers of resin and reinforcement materials are manually placed, and vacuum infusion, where a vacuum draws resin into a preform. Other techniques like compression molding, filament winding, and automated methods such as 3D printing are utilized to create intricate and specialized composite structures. Each process offers unique advantages in terms of precision, scalability, and efficiency, catering to diverse industry needs. As technology advances, newer methods are emerging, promising faster production cycles, reduced waste, and increased customization, driving the evolution of composite manufacturing towards more sophisticated and versatile methodologies.

Bonding and welding play vital roles in the assembly and fabrication of composite materials, offering methods to join components together effectively. Bonding involves the use of adhesives or bonding agents to create strong connections between different composite parts or between composites and other materials. Adhesives provide uniform stress distribution, enabling lightweight and durable structures. On the other hand, welding techniques like ultrasonic welding or induction welding are employed specifically in thermoplastic composites, where heat is used to melt and fuse the materials together.

JEC Group has announced its JEC Innovation Awards finalists, 33 total from 11 categories. Winners will be announced at JEC World 2020 on March 4.

Braided thermoplastic composite frame enables lightweight, recyclability and high-volume manufacturing.

The gantry-based filament winding system is designed to produce as many as 600,000 plastic-lined, glass fiber-overwrapped liquefied petroleum (LPG) gas pressure vessels per year.

The real impediment to use of thermoplastic composites in critical control surfaces is an education gap.

Scotsman is a direct-to-consumer, tailor-made electric kickscooter with continuous carbon fiber/thermoplastic unibody frame, handlebars, stem and baseboard.

Hexcel is showcasing its resins, thermoplastic UD tapes, epoxy prepregs and additive manufacturing technology.

Huntsman Advanced Materials used the 2017 CAMX show to showcase new products from its Advanced Materials and Huntsman Polyurethanes divisions, including advanced composite resin systems and adhesives.

Accurate geometry modeling and equivalent material property approximations captured by WoundSim will play a role in improving COPV analyses.

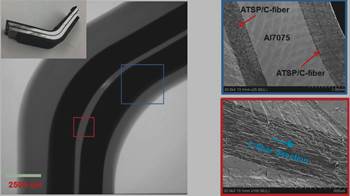

Aromatic thermosetting copolyester offers unique properties, availability in multiple form factors.

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.