Search Results

Showing 191 – 200 of 777 results

Processes in composites manufacturing encompass a diverse array of techniques employed to fabricate composite materials. These processes include methods like hand layup, where layers of resin and reinforcement materials are manually placed, and vacuum infusion, where a vacuum draws resin into a preform. Other techniques like compression molding, filament winding, and automated methods such as 3D printing are utilized to create intricate and specialized composite structures. Each process offers unique advantages in terms of precision, scalability, and efficiency, catering to diverse industry needs. As technology advances, newer methods are emerging, promising faster production cycles, reduced waste, and increased customization, driving the evolution of composite manufacturing towards more sophisticated and versatile methodologies.

Bonding and welding play vital roles in the assembly and fabrication of composite materials, offering methods to join components together effectively. Bonding involves the use of adhesives or bonding agents to create strong connections between different composite parts or between composites and other materials. Adhesives provide uniform stress distribution, enabling lightweight and durable structures. On the other hand, welding techniques like ultrasonic welding or induction welding are employed specifically in thermoplastic composites, where heat is used to melt and fuse the materials together.

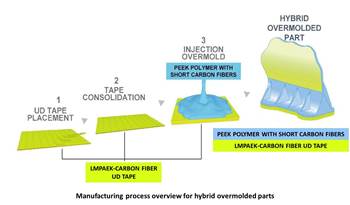

Novel hybrid overmolding technology achieves novel thermoplastic composite parts to replace machined aluminum components on commercial aircraft, as well as reduce manufacturing costs and timeline.

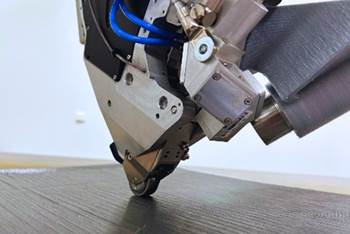

This compact cell brings together 3D printing, AFP and milling aided by a comprehensive software program, further simplifying the manufacture of complex thermoplastic composite aerostructures in the future.

Typically separate processes, the company’s new vessel winding head (VWH), merged with a multiple tape laying head (MTLH) progresses composite pressure vessel development.

Multiple metal additive technologies are gaining market acceptance and interest for composite tooling used in processes ranging from short-fiber injection to autoclave-cure prepreg.

Qarbon Aerospace exhibits its capabilities in manufacturing composite components and assemblies, highlighting its proficiencies in major assembly and systems integration, automated layup, hand layup, high-temp composites and core fabrication.

The LiMeCH project, led by the AMRC, Tinsley Bridge and Performance Engineered Solutions, developed filament-wound CFRP-metallic roll bar prototypes, with additional advances in joint bonding the hybrid materials.

ÂÌñÏ×ÆÞ webinar topics range from structural adhesives to automated fiber placement (AFP) to thermoplastics to composites repair, and much more.

Companies like Syensqo, Weav3D, Toyota, CompositeEdge and Teijin Automotive Technologies are recognized for their composites-forward approaches to more sustainable, energy-efficient automotive efforts.

As 2024 begins, we look at trending topics and our most-read stories in 2023, plus highlight new content for the new year.

More comprehensive product specifications added to adhesive Technical Data Sheets, including the addition of water contact angles, aids in improving effective bonding results, performance.