Search Results

Showing 11 – 20 of 276 results

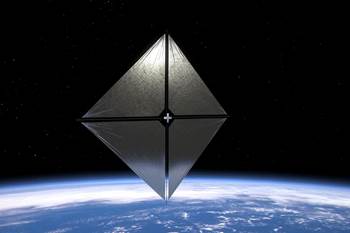

Sunlight-based propulsion system, supported by carbon fiber-reinforced booms, will undergo weeks-long testing to demonstrate and verify its capabilities.

Three key Tier 1 structure suppliers for Overture’s wing, fuselage and empennage, the aircraft’s systems configuration, engine architecture developments and more were shared at the Paris Air Show press conference.

FAA issues special flight authorization (SFA) for Boom Supersonic test flights, planned for later this year in the Black Mountain Supersonic Corridor in Mojave, California.

Since its rollout in 2020, the supersonic demonstrator has claimed several achievements, including a recent experimental airworthiness certificate and authorization for test pilot flights, further validating Overture’s development.

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Composite supersonic airliner Overture is on track to enter production in Greensboro, North Carolina by 2024.

German and Canadian research centers will implement joint projects in advanced technologies to foster innovation, promote international exchange of expertise and support talent mobility.

Cost-competitive carbon fiber-reinforced epoxy crane design uses CompoTech’s automated composites processes, eliminating welding or heat treatment and producing 50-70% stiffer structures.

A new approach for high volumes of small satellite structures uses low-CTE, low-cost CFRP cellular core, robust single-ply skins and modular panel systems to cut lead time, labor and cost for reflectors, solar arrays and more.

U.S. airline signs first commercial agreement with Boom Supersonic for 15 of its composites-intensive aircraft, Overture. The aircraft cuts travel time in half and operate on up to 100% sustainable aviation fuel.