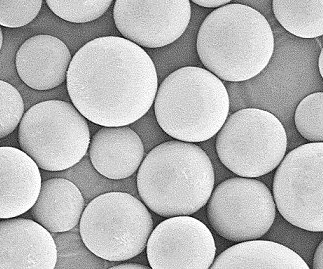

Spherical polyamide particles developed for 3D printing

Specifically designed for additive manufacturing, Toray’s new spherical synthetic particles can be used to produce high-strength, heat-resistant 3D-printed parts.

Source | Toray

A new technique from Toray Industries Inc. (Tokyo, Japan) has been developed to more simply produce micro-level spherical particles of polyamide with high melting points, such as polyamide 6 and polyamide 66. Specifically designed for additive manufacturing, Toray’s new spherical synthetic particles can be used to produce high-strength, heat-resistant 3D-printed parts.

Polyamide particles, many of which are non-spherical in shape and have low melting point, such as polyamide 12, are used as materials in powder-based 3D printing. To create higher-quality 3D-printed objects, truly spherical particles with higher fluidity and uniform fillability are ideal, and higher melting points are required to build parts with high strength and heat resistance.

The drawback with conventional production techniques, according to Toray, has been the difficulty of creating truly spherical polyamide particles with the high melting points that needs handle with high-temperature conditions. Toray says it has created a new technique to produce truly spherical particles at the same time as the polyamide is polymerized from the monomer, and is able to handle polyamide materials at a range of melting points. Moreover, Toray says its technique makes it possible to control average particle sizes between several microns through several hundred microns, enabling creation of uniformly-sized particles.

Toray says it will continue to establish scale-up technique to apply the technology to automotive and other parts.

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Hybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

.jpg;width=70;height=70;mode=crop)